Food Safety

20/09/2023 |

Food Safety: Key element of corporate strategy in the food industry

Would you like advice from our experts?

Find out here, with the help of the following frequently asked questions, how a targeted product inspection equips you for the future and how you can find solutions for your priorities.

FAQs

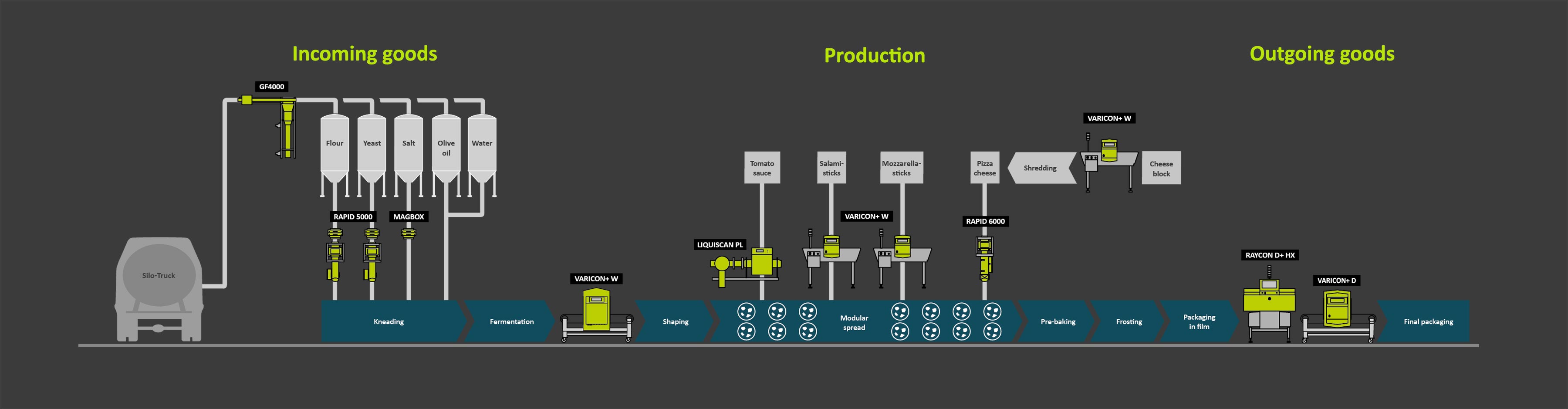

- How

to maximize product and process quality?

With the best hardware and software solutions along your production line from the incoming goods through the production to the outgoing goods. - How

can you automatically adjust sensitivity settings to internal standards?

With innovative software, sensitivity can be set to factory or audit standards at the touch of a button. This reduces rejects and minimizes good material loss. - How

can you automate your compliance process?

Continuous monitoring or automatic function test module lead to immediate detection of deviations and increas the stability of the production process. - How

can you prove and document compliance?

With a documentation tool that provides evidence that the desired quality targets for the respective product are achieved. - How

do you compensate a strong product effect in your products?

With artificial intelligence in its best form. This can achieve almost complete compensation of the product effect, metal detection in metallic packaging and RFID tags. - How

do you have all relevant control points information at a glance?

With a (Link Insight.WEB) browser-based, intelligent data management. A software as a service that enables transparency, optimisation of production, individualisation and documentation. - How

can you make Industry 4.0 a reality?

With the right software and hardware for digital networking including a wide range of interface modules and secure conformity. - How

can the highest product quality be combined with the highest throughput?

With innovative high-tech X-ray inspection that works very quickly and reliably at up to 1000 rpm.

- How

to extend the lifetime of the machines and ensure the highest food safety?

With annual maintenance and warranty packages. The life of your equipment is extended with maintenance, repair and retrofitting. - How

can you become more successful in the competition for highly qualified

operating personnel?

With simple operating concepts in hardware and software design, e.g. Auto-Learn function

- Auto-Learn function automates product-specific device settings

- Audit-Check guides through the test routine and logs all steps

- Consistent help menu supports the operator - How

can you automatically guide your operator through compliance processes?

With an integrated process wizard tool that performs regular audit checks.

- How

can you protect against incorrect machine settings?

With the checkpoint function of the detection devices. Checkpoints are used to recover product parameters, reconstruct individual products and track changes. - How

can maximum security be achieved?

With a higher level security package that offers checkpoint functions. This exceeds international standards, SQF, IFS, FSSC 22000, BRC and others. - How

to comply with internal data protection and operational security regulations?

With the definition of different user groups, individual access authorisations and a "Login2Go" function that saves the date on a USB stick - optionally RFID login. - How

can the highest hygiene standards be maintained?

With quick belt change and fast cleaning of the X-ray units. Simplified cleaning through open, modular design, access and removal of the belt without tools and suspension system for radiation protection curtains. - How

can you qualify your unskilled staff for X-ray machines?

With an auto-learn function of the X-ray machines. The Auto-Learn function offers simple and intuitive operation. The configuration of the different filters is done by the machine itself and the detection sensitivity is automatically adjusted. - How

to get quick advice and help in machine emergencies?

With remote maintenance via augmented reality. The augmented reality technology, which accesses your machine directly via an Ethernet connection, enables technicians and engineers to respond very quickly.

Conclusion

Food

safety is not just a trendy keyword, but a key element for companies in the

food industry. This article makes it clear that high quality is not only

ethically desirable, but also makes good business sense. In fact, profitability

in the long term can only be achieved through consistent quality assurance.

Companies committed to responsible food production recognise that food safety

is a priority. In this context, it is not enough to carry out controls only at

the end of the production chain. Effective assurance of food safety requires

monitoring at every single checkpoint of production.

Food Safety is our Passion.

Your Questions

on Management Control - learn our answers here

on Quality Assurance - learn our answers here

on Operations Excellence - learn our answers here

Unsere Lösungen

Sesotec Compliance Paket

Sesotec Integrated

Compliance Monitoring (ICM)

Sesotec Artificial Intelligence (THiNK)

Sesotec Digital Networking

(INTERLINK)

Sesotec

High-Tech X-ray Inspection (RAYCON)

Sesotec Maintenance

and warranty packages

Sesotec Remote Support