Food Safety

19/12/2023 |

Food safety: A synergy of hardware and software

-

Artificial

intelligence for precision: improving the accuracy of metal detection using AI

methods can significantly increase the reliability of detection systems. The

reduction of false alarms due to product influences is a decisive step towards

increasing efficiency in processing and quality control. It is also important

to exclude metallised packaging from the detection process in order to ensure

more precise sorting and separation of materials.

-

AI-based

visualisation software provides essential data and facts that are essential for

process optimisation. It makes a significant contribution to planning

reliability by enabling precise predictions and analyses. In addition, this

software plays a central role in production and quality control by clearly

visualising complex information and thus enabling efficient monitoring and

control. Another advantage of this software is that it enables continuous

learning through the use of artificial intelligence, allowing it to constantly

adapt to changing conditions and thus deliver more accurate results.

-

Intelligent

documentation software enables seamless and efficient documentation, which is

essential for guideline-compliant production. The accuracy and reliability of

production processes are significantly improved. Another key aspect of

intelligent documentation software is that it reduces or even eliminates the

need for manual testing. This results in significant time and resource savings

as automated processes increase efficiency while minimising the risk of human

error.

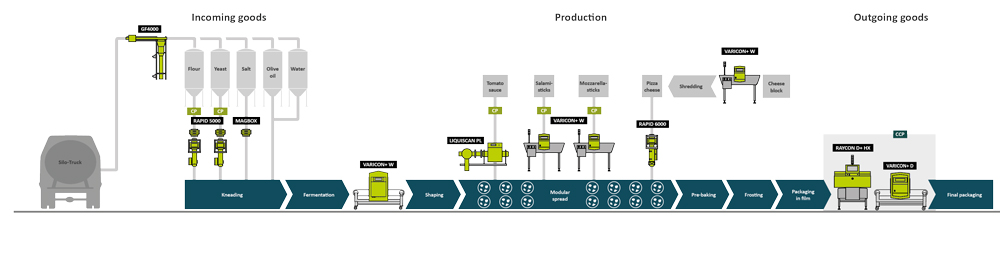

- Connectivity

and real-time analysis: Modern software enables comprehensive connectivity of

all machines and systems, seamlessly networking the entire production process

from incoming goods to outgoing goods. This integration makes it possible to

analyse the recorded live data in real time. The combination of networking and

immediate analysis enables proactive intervention, which not only minimises

downtime but also significantly increases overall system effectiveness.

Why software solutions are important for food safety:

-

Traceability:

software solutions enable precise traceability of food along the entire supply

chain. From farm to fork, companies and authorities can trace the origin of

food and react quickly and efficiently in the event of a recall.

-

Data

analysis and early warning systems: Modern software solutions utilise advanced

analysis techniques to process large volumes of food safety data. This allows

early warnings of potential risks to be issued, preventing quality losses or hazard

food safety.

-

Quality

control and compliance: Software solutions enable efficient monitoring of

compliance with quality standards and legal regulations. They automate

inspections and audits, facilitate documentation and help to identify

deviations. This enables companies to ensure that their products meet the

highest quality and safety requirements.

-

Increased

efficiency: The automation of processes in the food industry through software

solutions helps to increase efficiency. This not only means cost savings, but

also a reduction in human or machine errors, which often lead to food

contamination.

-

Precaution

and prevention: By continuously monitoring and analysing data, software

solutions can help to identify potential risks at an early stage and take

preventive measures to avoid food contamination and scandals.

-

Optimisation

of the value creation process: The value creation process is significantly

improved through the seamless monitoring and networking of all control points,

from incoming goods to outgoing goods, both critical and non-critical control

points. Software solutions thus ensure integral control and increased

efficiency across the entire production process.

→ Foreign body control "End-of-line" is good - "Along the line" is better - Last but not least - customer transparency: Consumers are becoming increasingly demanding and want to know more about the origin and quality of their food. Software solutions enable companies to create transparency in the supply chain and provide consumers with detailed product information. This strengthens confidence in food safety.

Conclusion

Discover the innovative software solutions from Sesotec:

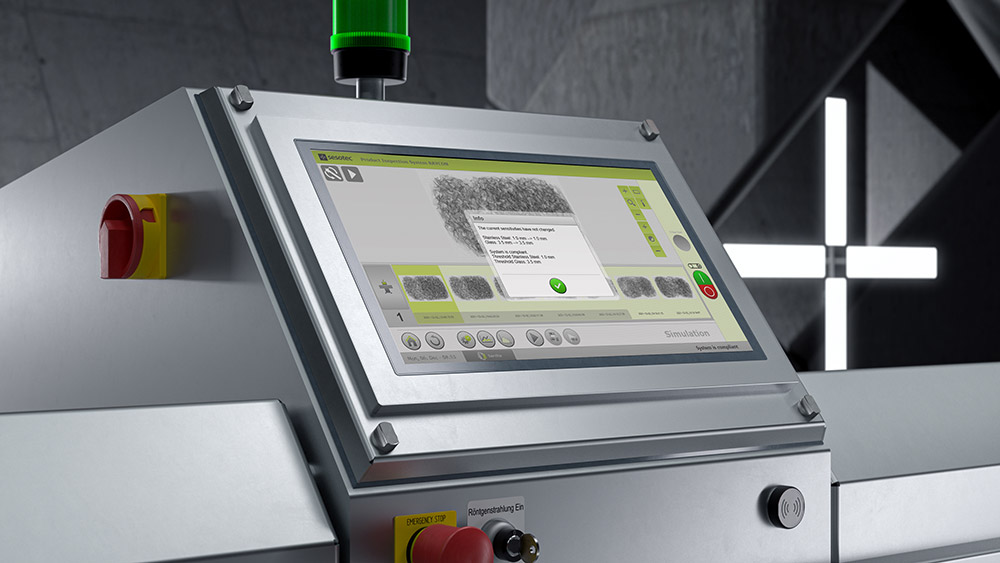

Sesotec THiNK - Metal detection with artificial intelligence

Sesotec Compliance Package - software for seamless and efficient documentation

Sesotec Insight Web - Visualisation software for metal detectors