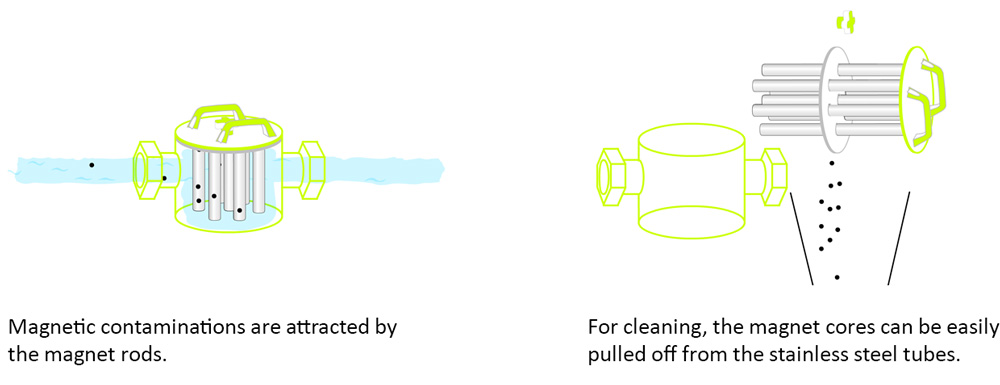

Magnet systems for liquids and pastes

The food, pharmaceutical and chemical industries all have the highest demands when it comes to product quality. Our magnet separators have been specifically designed to meet their requirements. The separators integrate without issue into existing conveyor pipes and reliably protect consumers from magnetic metal contaminants.

Filter magnets for liquid and paste products

integrate into pressure conveyor pipes. They remove minute magnetic metal

contaminants from the goods that flow through. More information on how

Sesotec magnet separators work is available

here.