The guarantee of high quality of plastic flakes and regrind is crucial in determining whether plastic processors and manufacturers can profitably use and sell plastic recyclate.

Depending on how the recyclate will be used, but also as a means of evaluating the recycling sorting process, elaborate manual, visual, or thermal sample analyses are often necessary in order to assess the quality of a batch of materials. Such sample analyses are hardly representative, and furthermore require additional resources, costs, and time.

Precise

Automatically performs precise, reproducible analyses of material samples with the help of up to three integrated sensors:

Profitable

FLAKE SCAN virtually eliminates the need for labor-intensive sample analyses and significantly reduces the efforts involved in performing manual, visual, and thermal inspections. By enabling quick and informed decisions about the viability of plastic flakes and regrind, FLAKE SCAN helps increase the profitability of using plastic recyclate. Furthermore, the results provide valuable insights into the recycling process and the functionality of various components.

Looking for more information or advice? Contact us

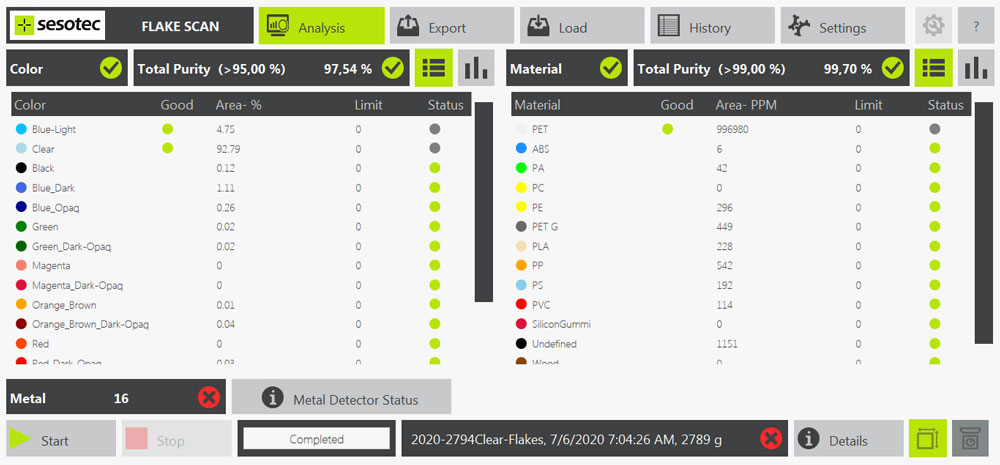

Analysis results can be displayed either in a table or in diagrams. Should predefined limits for polymer types or false colors be exceeded, this will be marked accordingly in the table. The amount of identified metal contaminants will also be displayed.

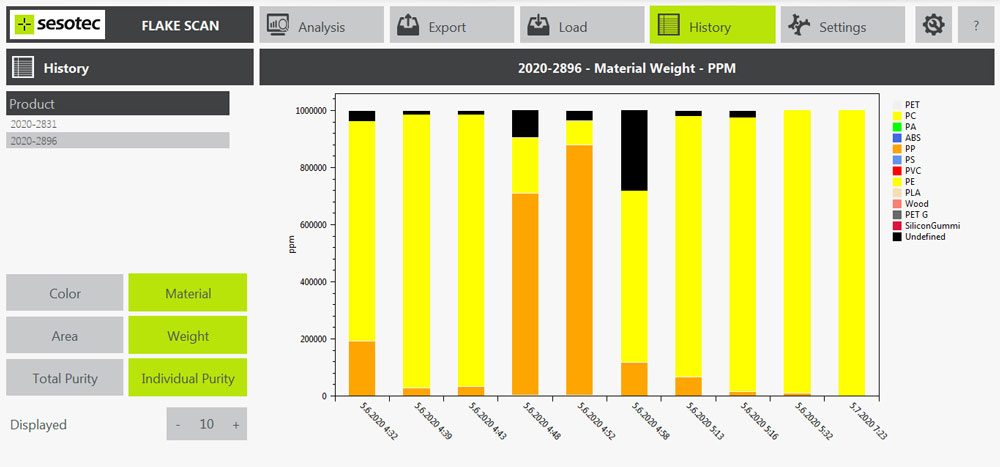

From the “History” menu, you can quickly compare the purity and color quality of the current batch with those of archived samples.

With

optional VISUDESK visualization software, you can see all process and

usage data from your Sesotec sorting and metal detection devices in one

comprehensive dashboard. This is possible by means of an OPC UA machine

communication protocol implemented in each device as well as your

company server.

The browser-based interface is accessible

both on desktop and mobile. This dashboard provides a comprehensive

overview of your entire sorting line as well as information about

specific groups of devices, enabling you to quickly create equipment

configurations and automate product changes.

Seamless backwards compatibility is possible via established VISUTEC protocols. Customizable e-mail and text alerts keep you informed about critical developments in the machine status.

Reiling relies on sound quality inspection with sorting and material analysis systems from Sesotec

Sorting and Detection systems for every stage of the Circular Economy in the plastics industry.

VISUDESK, the new visualisation software for sorting machines, makes your sorting processes transparent and enables direct control for higher efficiency and higher profitability.