Sustainability and added

value

Sustainability and added

value

Resource

scarcity, environmental degradation, and climate change demand a new approach

to sustainable business. The

solution is a circular economy in which waste is repurposed as a valuable raw

material. For

profitable recycling, material purity is essential.

Our

intelligent technologies and services help recycling companies to

profitably produce secondary raw materials of the highest quality. Material

cycles are closed.

Sustainability, environmental protection, and profit go hand in hand.

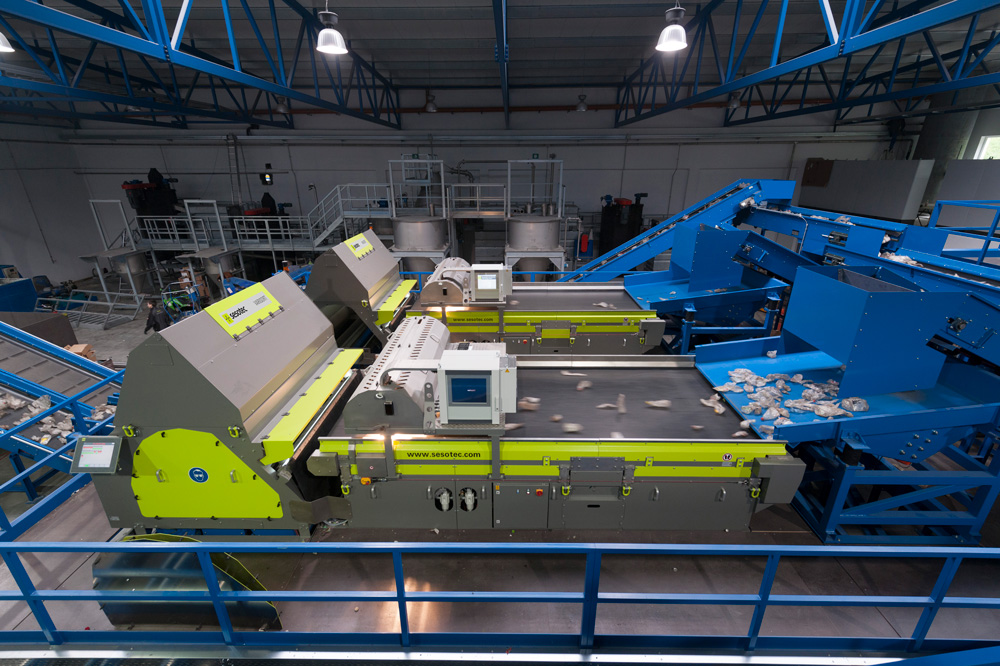

Many materials can be recycled to create new, high-quality products.

However, the purity of the material is crucial to efficient recycling. Our

detection, separation and sorting systems remove contaminants and separate mixed material

flows into homogeneous, unmixed fractions. By doing so, they facilitate a high

degree of material quality and profitable recycling. Material analysis systems can be used to

precisely determine the purity of plastic flakes.

With our versatile range of equipment, we can install detection, separation, or sorting equipment at precisely the process stage where it can make the biggest impact on product quality, plant availability, and material recovery rates. All from a single source!

Higher material quality and greater added value: In order to recycle glass or metal economically, the recyclable material which is collected must have a high degree of purity. Our separation and sorting systems precisely remove contaminants and separate material flows into homogeneous, unmixed fractions. Recycling rates of up to 100 per cent are possible with our systems for applications that involve recycling used glass and some plastics.

Higher

throughput and minimal loss of good material:

Our separation and sorting systems offer maximum efficiency. You will see this reflected both in high rates of material throughput as well as in precision functioning that results in minimal loss of good

material. Through every stage of machine design, our

equipment is optimized for reliable system availability, quick cleaning, and

easy maintenance.

Our systems sort the following materials, among others:

Blue Competence is an

initiative of the VDMA (www.vdma.org) to promote sustainability in mechanical

and plant engineering, but also to make sustainable solutions known to the

industry. With our partnership, we commit ourselves to adhering to the 12

sustainability principles of mechanical and plant engineering

(www.bluecompetence.net/about).

The plastics industry is under pressure. Between climate change, excessive consumption of finite resources, and vast amounts of plastic waste in the world’s oceans, plastics are coming to be seen in a different light by politicians, businesses, and consumers alike. Read in our e-book about the most important factors of a functioning circular economy, especially which challenges and opportunities exist for recyclers and plastics processors.

Which building blocks are necessary for a closed-loop plastic circular economy and which important parameters there are to close the loop, we will go into in the second part of the

"Circular Economy"

article series.

In this white paper, we explain the developments in the field of artificial intelligence for sorting recycling and show how you can benefit from them to make your processes more precise, more sustainable and more profitable.

Download

Reiling is prepared to fulfill this need, offering an entire range of services from collection (full service or DIY), to processing (converting bottles to flakes), to creating carefully controlled end products. For those who will eventually buy the flakes, color and material purity are of central importance, as high-quality starting materials are needed to manufacture new products.

Foreign materials posed the biggest challenge to the new plant.

Contaminants such as ceramics, stones, porcelain (CSP), metals, paper,

and plastics comprise as much as 15 to 20% of the total weight of all

collected glass waste. To overcome this challenge, KRS supplied a

sorting system that meets these requirements.

In a plant equipped with stateof-the-art (sorting) technology, Futurapet recycles plastic waste. The secondary raw materials obtained are returned to the plastics processing industry. When Futurapet was founded, General Manager Oğuz Engin and his t eam were looking for innovative solutions that efficiently deliver high-quality end products.

Reiling relies on sound quality inspection with sorting and material analysis systems from Sesotec

Reliable and precise sorting with multisensor sorting systems from Sesotec

Mission PET sees the circular economy mission in the consistent implementation of PET recycling. The bandwidth for the use of recycled PET material is diverse. However, only high-purity rPET material also meets the requirements that correspond to those of virgin material. The demands placed on the recycling process for preparing the PET material are correspondingly high. Best decontamination and material cleaning of the PET starting material are the prerequisites for maximum purity of the end product.

Thanks to the new Sesotec technology, more valuable, dark cullet remains in the material cycle. The proportion of glass recovered is significantly increased once again and can be used to add value in high-quality melting applications.

Like in most recycling processes, companies such as World PET Recycling face the challenge of removing contaminants from recycled PET to meet the strict quality standards for food-grade materials.

Sorting and Detection systems for every stage of the Circular Economy in the plastics industry.

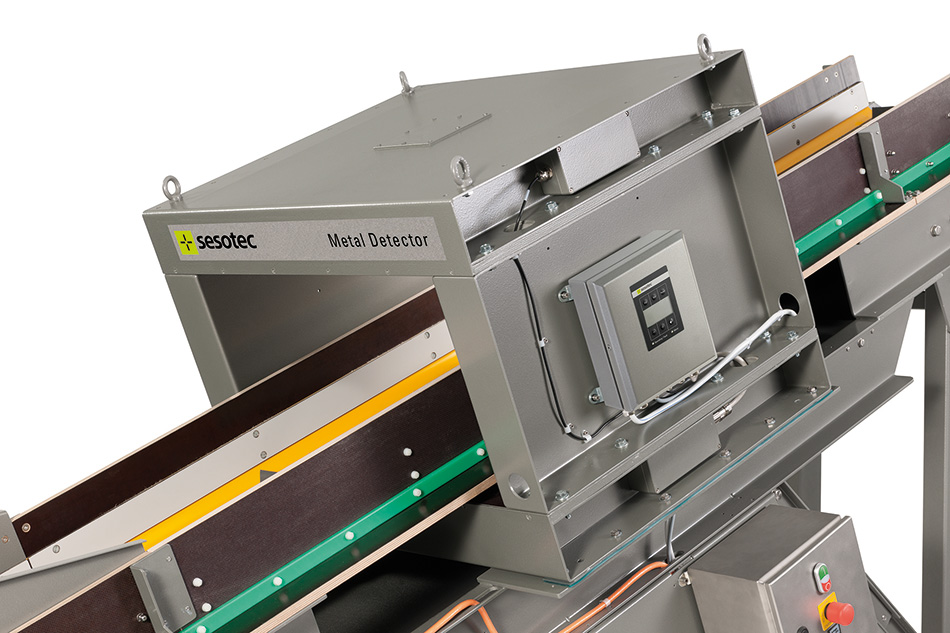

Splitable metal detector for installation on conveyor belts and material chutes

Multi-Sensor Sorting System for the Plastics Recycling Industry

Multi-Sensorsortiersysteme für die Recycling-Industrie

VISUDESK, the new visualisation software for sorting machines, makes your sorting processes transparent and enables direct control for higher efficiency and higher profitability.

Looking for more information or advice? Contact us