UNDERSTANDING CIRCULAR ECONOMY

Article series on the plastic cycle

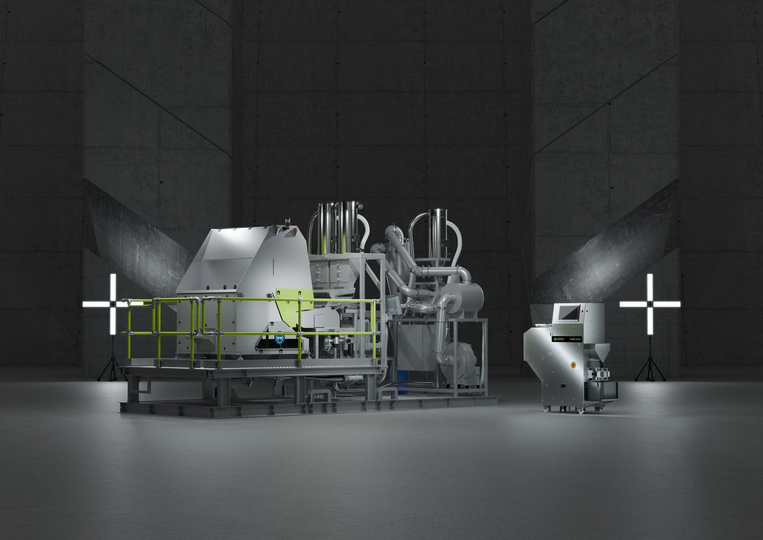

Our collection of articles on the topic of Circular Economy deals with various aspects of the plastic cycle and, in this context, also delves into the specific challenge of foreign body detection in more detail.

If you would like to speak directly with us about a topic related to the Circular Economy, please do not hesitate to contact us.