Company

22/02/2024 |

Sesotec at Anuga FoodTec 2024- Foreign body management all along the line

Sesotec Highlights: Hardware and software solutions along the line The RAYCON D+ HX LW Hygienic X-ray inspection system, the curtainless high-end model specially designed for the inspection of unpackaged products such as fresh, chilled or frozen meat products, is characterized by maximum detection accuracy and exceeds both the safety and hygiene requirements of food regulations. The RAYCON EX 1 X-ray inspection system offers a solution with maximum performance and ease of use at a moderate price. A special highlight at the trade fair will be a live demonstration of how X-ray technology guarantees maximum detection accuracy even at high throughput rates of up to 1000 items per minute.

The VARICON+ D metal detection system is equipped with the INTUITY THiNK metal detector. This technology is based on artificial intelligence and is predestined for difficult applications, such as meat products with high intrinsic conductivity. INTUITY THiNK makes it possible to achieve extremely high sensitivities and avoid false triggering, while minimizing food losses. The other conveyor belt solution VARICON+ GLS MF works with multi-frequency technology and is the standard model for inspecting piece goods and bulk goods on a conveyor belt with very good detection accuracy. At Anuga FoodTec, Sesotec will be presenting the GLS MF tunnel metal detector with a 7-inch display together with the new Insight.HMI software. The associated advantages: Permanent machine and product overview, extended links for daily use, configurable dashboards according to the user role and increased ease of use (optimized operator guidance and control of devices via mobile device, particularly advantageous if a device is difficult to access).

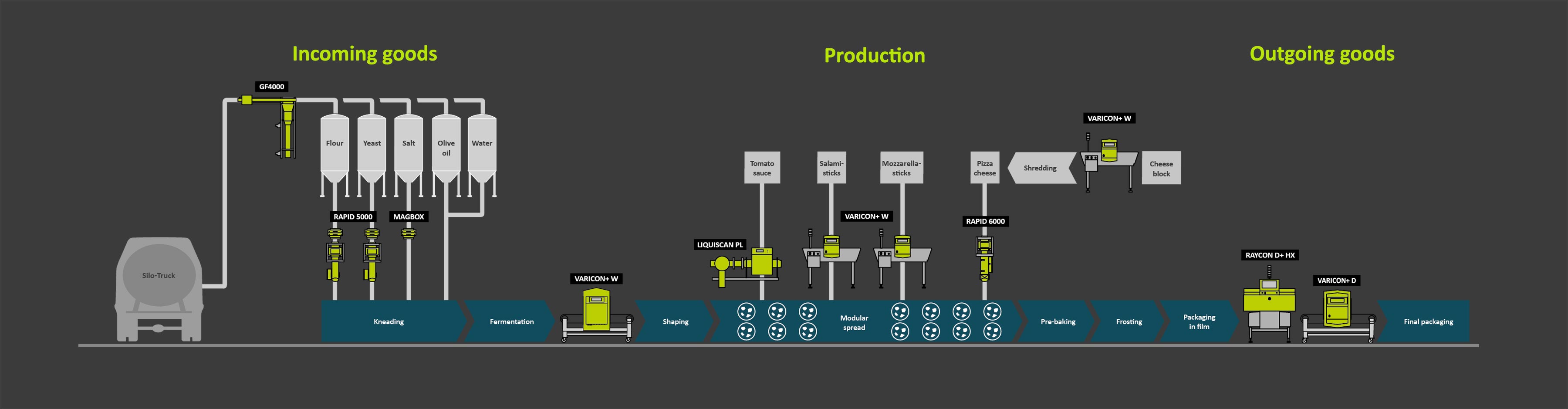

Sesotec also offers a broad product portfolio for a wide range of applications in order to increase profitability and process efficiency along the entire value chain. Examples include the RAPID 5000 metal separators for the inspection of bulk materials in free-fall conveying lines and the GF 4000 for use in pneumatic conveying lines. Add-ons that will be demonstrated live at the trade fair: On the GF 4000, automatic function monitoring, which replaces manual function tests, and on the RAPID 5000, both an automatic and a manual testing device. The LIQUISCAN VF IC metal separator for liquid and pasty products can be quickly and easily integrated into existing piping systems and connected to all standard vacuum fillers, pumps, clippers and sausage meat filling systems. Suitable separation systems ensure the reliable removal of all metallic contaminants.Compliance Paket

The Compliance Package is an innovative software solution for seamless and efficient documentation of compliant food production. The package therefore meets all the requirements of production managers, quality managers and top management. It offers functions such as Audit Check, Sensitivity Forecast, Compliance Mode, Integrated Compliance Monitoring (ICM) and Integrated Validation Process (IVP).

Insight.WEB visualization software

Food manufacturers and processors are confronted with constantly increasing quality requirements and ever more complex processes. The data collected offers great potential for process optimization, planning reliability and production and quality control. quality control. Unfortunately, this potential often remains untapped. In view of topics such as Industry 4.0, the increasing use of standard modules and the importance of seamless process documentation, it is essential to have a powerful tool to know what was produced, when, how and where at all times.

The solution for these requirements is the Anuga FoodTec highlight Insight.WEB from Sesotec. The browser-based platform offers customer-oriented smart data management. At a glance and through intuitive customization, equipment performance, upcoming maintenance, potential for process optimization as well as important changes and warnings can be displayed easily and clearly. Thanks to Sesotec's many years of experience and the latest methods of artificial intelligence, food manufacturers and processors always have access to important figures, data and facts with the optional visualization software.

Sesotec service at a new level

In the service area, Sesotec offers various services that support customers in improving the efficiency, productivity and connectivity of production lines throughout their entire life cycle. These services can be used in incoming goods as well as during production or outgoing goods. Innovative and digital service concepts will also be presented at Anuga FoodTec. One example of this is predictive maintenance. This involves analyzing real-time data from networked machines and systems in order to be able to intervene in good time before things come to a standstill. This helps to improve overall system effectiveness, increase production and reduce costs.

"Food safety is the passion of the Sesotec team, which visitors will feel in every respect. We are not just presenting products. We are presenting our entire know-how, which is based on decades of experience from thousands of customer projects. Our innovative solutions enable customers in the food industry to work more profitably and sustainably. We look forward to interesting discussions," says Johannes von Stein, Sesotec Vice President Sales Food.

Further information www.sesotec.com/emea/en/lp/anuga-2024