Almi, an Austrian company headquartered near Linz, and one of the

leading manufacturers of quality flavourings and additives for sausage,

meat, ham and fish products, uses Sesotec “Hygienic Design” metal

detectors throughout their entire production process.

Separately purchased recyclate often contains various different polymers as well as metal contaminants such as aluminum, brass, and stainless steel. Learn in our Case Study how Sitraplas has solved this problem.

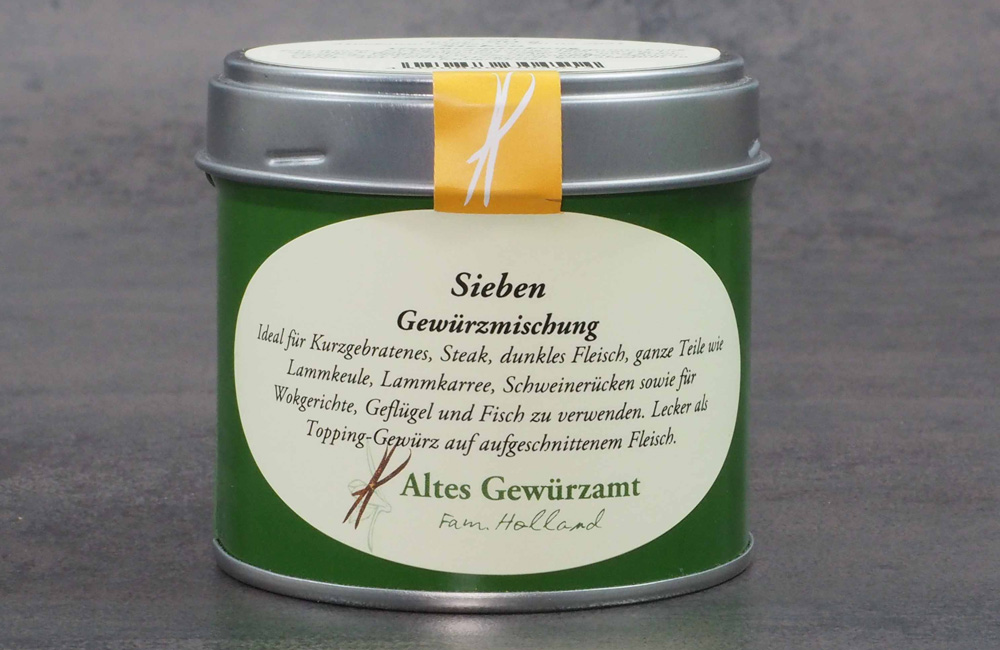

The „Alte Gewürzamt“ produces 120 tons spices and spice mixtures per year on 4.000 square meters. The HACCP analysis revealed an increased risk of contamination with metal, stones and glass. An inspection at the outgoing goods was therefore required to meet the quality standards.

SITRAPLAS GmbH is a producer of high-performance engineering plastic compounds. Unplanned downtime is a nightmare for every company, but especially for continuous production facilities. When metal separators are networked with plastic processing machines, the flow of information between machines can be monitored.

Pneumatic conveying is common within the milling industry to move large volumes of products. This firm was looking for a metal detection solution to provide enhancements to their food safety initiatives (GFSI) within the challenge of pneumatically conveying the finished product to bulk carriers.

To avoid any metal in the powder, CIPSA wanted to inspect the PVC compounds before they enter the pelletizer. This was to protect the extruder screw from damage and avoid expensive production stops.

Reiling is prepared to fulfill this need, offering an entire range of services from collection (full service or DIY), to processing (converting bottles to flakes), to creating carefully controlled end products. For those who will eventually buy the flakes, color and material purity are of central importance, as high-quality starting materials are needed to manufacture new products.

While processing virgin glass-filled material together with regrind, the same problem was coming up up over and over again. Metal inclusions were clogging the hot runners of the molds, leading to as many as 10 emergency stops and 2 to 3 costly repairs per month. After careful consideration of the production environment and manufacturing specifications, the metal detection system PROTECTOR 40 was installed along with the magnet system SAFEMAG at the feed hopper of the injection molding machine.

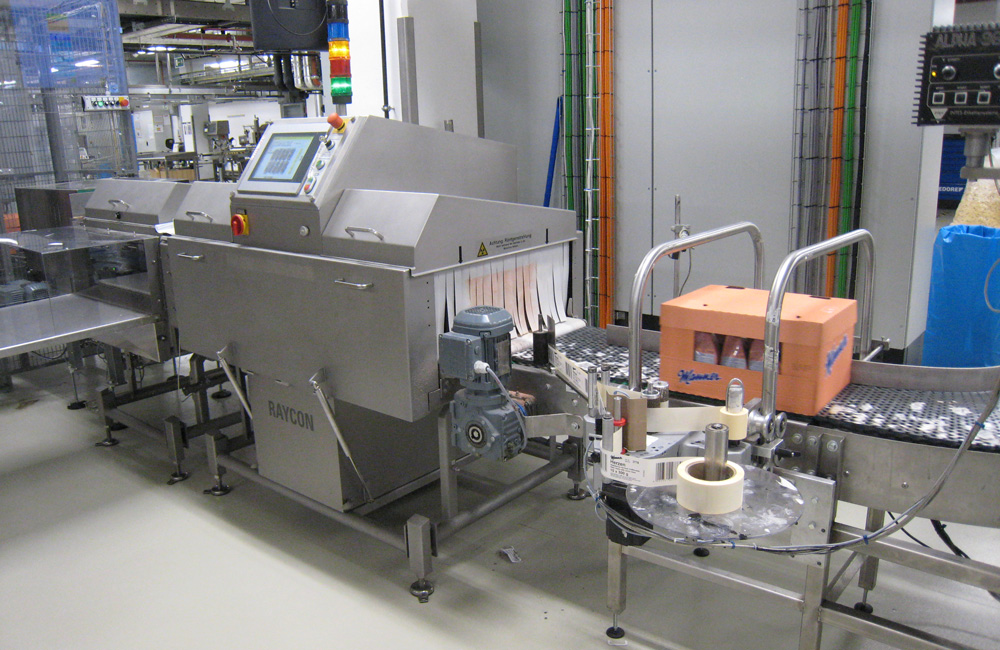

The Backwelt Pilz produces pre-baked and pre-cooked deep-frozen baked goods, for the food retail trade, petrol station shops and system gastronomy. In order to ensure that bread and rolls are absolutely free of foreign bodies, the Backwelt Pilz decided, in addition to the existing metal detectors, also to install RAYCON D+ X-ray inspection equipment for packaged products.

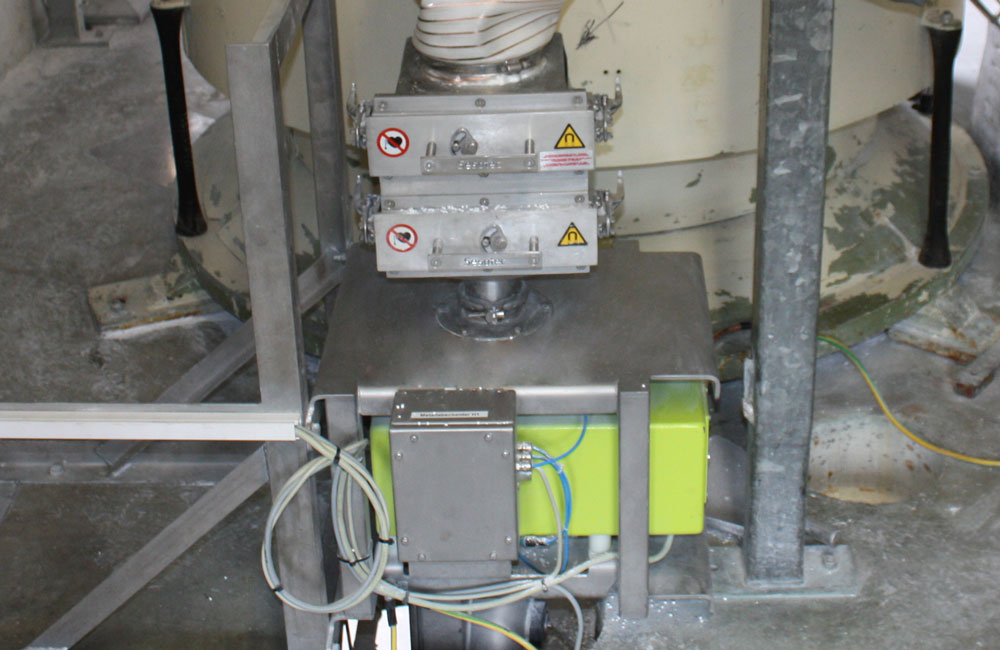

When this customer looked for a metal detector, he expected this system to remove metallic contaminations from dry spices inspected in pneumatic pipes without causing any interruptions of the production process.

The quality requirements of the chemical industry are particularly high. Metal detectors play an essential role in the refinement of solids to ensure a consistently high product quality and safety. At the same time, the customers expect quick setup times to achieve high flexibility and efficiency.

Founded in 1890, the Josef Manner & Comp. AG is the number one specialist for wafers, dragées,

and marshmallow products

in Austria.

As a leading

manufacturer of product

inspection technology, Sesotec supplied Manner with three RAYCON x-ray systems to help them renew their IFS certification in 2019. The solution was a success:

their IFS certificate was renewed and both production

sites continue to operate at the highest level of accreditation.

Founded in the 1960s, H. Loidl Sausage Producers and Distributors GmbH & Co KG attributes their rapid growth to the high quality of their salami products. Once ripe, some Loidl salami products are packaged in slices. This requires

removing the casing and the aluminum clips by hand. In some cases, residue from the aluminum clips remains on the salami. The standard metal detection solutions Loidl had used up un til that point were not sensitive enough to reliably detect the metal contaminants. So Loidl turned to Sesotec in search of a solution for detecting and automatically rejecting metal contaminants from salami sticks.

For more than 335 years and 14 generations, Rubinmühle has been managed by the Rubin family.

Customers in Europe and beyond benefit from their reliable and flexible supply of innovative, high-quality grain products.

As quality requirements have become

more stringent over time,

Rubinmühle

commenced a search for a solution that could

inspect grain flakes with the best possible detection rates.

Among the favorite products of Tunacor Fishing Ltd are their fish sausages, which are especially celebrated in Spain. However, every now and then they would receive complaints from customers about bits of metal in the sausages.

FF Frischfleisch AG was searching for a way to fully trace 100% of products subject to complaints. Such a solution would require the systematic documentation of production.

In cooperation with Kundert, the Swiss sales partner, Sesotec was able to develop a solution to this challenge onsite.

Many customers face the problem of lacking the knowledge of which setting parameters can cause a significant change in product safety and process relevance. A validation process can aid these customers to overcome this challenge and take a successful path towards compliance with food safety standards. Such as process can also be used as a service.

Foreign materials posed the biggest challenge to the new plant.

Contaminants such as ceramics, stones, porcelain (CSP), metals, paper,

and plastics comprise as much as 15 to 20% of the total weight of all

collected glass waste. To overcome this challenge, KRS supplied a

sorting system that meets these requirements.

In a plant equipped with stateof-the-art (sorting) technology, Futurapet recycles plastic waste. The secondary raw materials obtained are returned to the plastics processing industry. When Futurapet was founded, General Manager Oğuz Engin and his t eam were looking for innovative solutions that efficiently deliver high-quality end products.

Reiling relies on sound quality inspection with sorting and material analysis systems from Sesotec

Milchwerke

Schwaben processes 410 million kilograms of milk and whey each year.

Metal

detection must be installed at various checkpoints to control for the quality

of dairy products. Butter and rice pudding, for example, are transported

through pipelines prior to filling. In

order to ensure these packaged products are free of metallic contaminants,

metal detectors are used.

As a new major company with the highest quality requirements, CREMER needs a powerful and reliable metal detection system to ensure that its production facilities meet international standards and reliably produce safe products. All in the interest of food safety.

Reliable and precise sorting with multisensor sorting systems from Sesotec

Mission PET sees the circular economy mission in the consistent implementation of PET recycling. The bandwidth for the use of recycled PET material is diverse. However, only high-purity rPET material also meets the requirements that correspond to those of virgin material. The demands placed on the recycling process for preparing the PET material are correspondingly high. Best decontamination and material cleaning of the PET starting material are the prerequisites for maximum purity of the end product.

EUROVERDE‘s entire product range is the result of a quality process at the highest level. In the field of foreign matter management, EUROVERDE has been using various metal detectors for years to separate metal particles of any kind from the products.

Thanks to the new Sesotec technology, more valuable, dark cullet remains in the material cycle. The proportion of glass recovered is significantly increased once again and can be used to add value in high-quality melting applications.

Our client in northern Germany employs around 600 people and produces single and double-sided adhesive tapes on production facilities that are among the most advanced worldwide. Raw materials for adhesive tape production can contain tiny metal particles. Even the smallest foreign object that enters production poses a significant risk.

As Plastiques ZD grew, it became necessary to find an environmentally friendly and cost-effective solution for recycling defective parts and production waste. The company turned to the long-time Sesotec partner, MAT Technologic, for a solution.

Viet UC faced the challenge of eliminating metallic contaminants from masterbatch to prevent particles from entering plastic mixtures during production. These contaminants could not only compromise the quality of the final product but also lead to machine downtime and customer complaints.

Like in most recycling processes, companies such as World PET Recycling face the challenge of removing contaminants from recycled PET to meet the strict quality standards for food-grade materials.