Case Studies

18/12/2023 |

Mission PET – Circular economy needs material cleaning with state-of-the-art technologies

Scarcity of resources, environmental pollution, and global warming, call to rethink new ways to work towards a sustainable economy. The solution is a Circular Economy, in which waste is used as a valuable source of raw materials. As far as plastics are concerned, the EU has already set the recycling targets: plastic waste should be reusable or recyclable in a cost-effective manner and thus become valuable secondary raw materials. The prerequisite for a wide range of possible uses of the recyclates is that the starting material is sorted and free of impurities. In order to achieve the EU recycling targets in the plastics sector, the recycling of PET plays an important role. This is exactly where the newly founded Austrian company Mission PET GmbH starts: PET recycling experts have joined forces on the ground of the Zellinger company’s eco-park in Feldkirchen-Gerling/Austria and have taken the challenges of their circular economy mission. Mission PET has set itself the target of an annual capacity of 14,000 metric tons of rPET pellets. In addition to the classic bottle-to-bottle application, the company also serves other areas of application for rPET pellets.

The challenge: Highest demands on rPET material for a wide range of applications

Mission PET sees the circular economy mission in the consistent implementation of PET recycling. The bandwidth for the use of recycled PET material is diverse. However, only high-purity rPET material also meets the requirements that correspond to those of virgin material. The demands placed on the recycling process for preparing the PET material are correspondingly high. Best decontamination and material cleaning of the PET starting material are the prerequisites for maximum purity of the end product.

The solution: Highest precision in material sorting

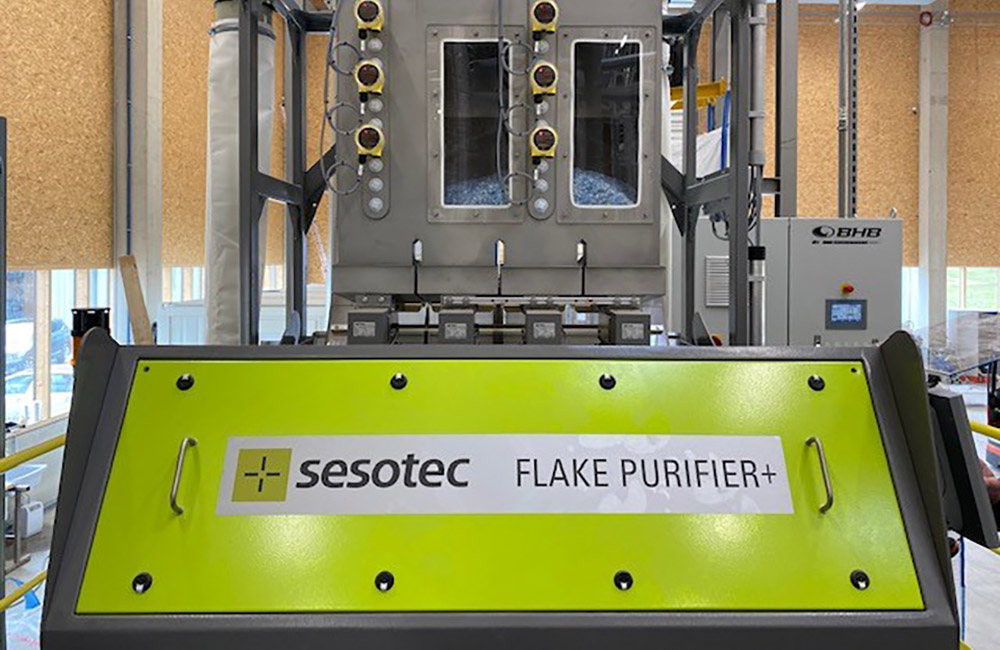

Thanks to the cooperation of primarily regional and professional project partners, the Mission PET plant could go into operation in March 2023. As an experienced project partner for sorting technology, Sesotec supplied the high-precision sorting system FLAKE PURIFIER+, which ensures the highest purity of flakes. In addition, Sesotec planned and engineered the steel structure, silo, plant control system, and BigBag stations for mixing the input fraction around the sorting system. Mission PET extracts high-quality pellets from pre-sorted, crushed and washed PET bottles. Pellets, which, in addition to a wide range of applications, can even be used in the food industry. Using the BigBag stations supplied by Sesotec, the incoming PET material is mixed in order to obtain uniform fractions. The high-precision FLAKE PURIFIER+ sorting system reliably detects and rejects unwanted plastics, off-colors and also metallic contaminants. The resort track in the FLAKE PURIFIER+ even makes it possible for material that has already been sorted out to pass through the sorting process again. This results in minimal loss of good material, while at the same time achieving high throughputs. The high-purity PET material obtained is then processed into pellets to be used instead of newly produced PET for the manufacture of a wide variety of products.

The customer benefit: highest quality for the circular economy mission

“We want to provide our customers with sustainable food-grade rPET pellets. Sesotec multisensor sorting systems guarantee our customers the best decontamination and material cleaning“, says Markus Huemer, Managing Director of Mission PET GmbH.