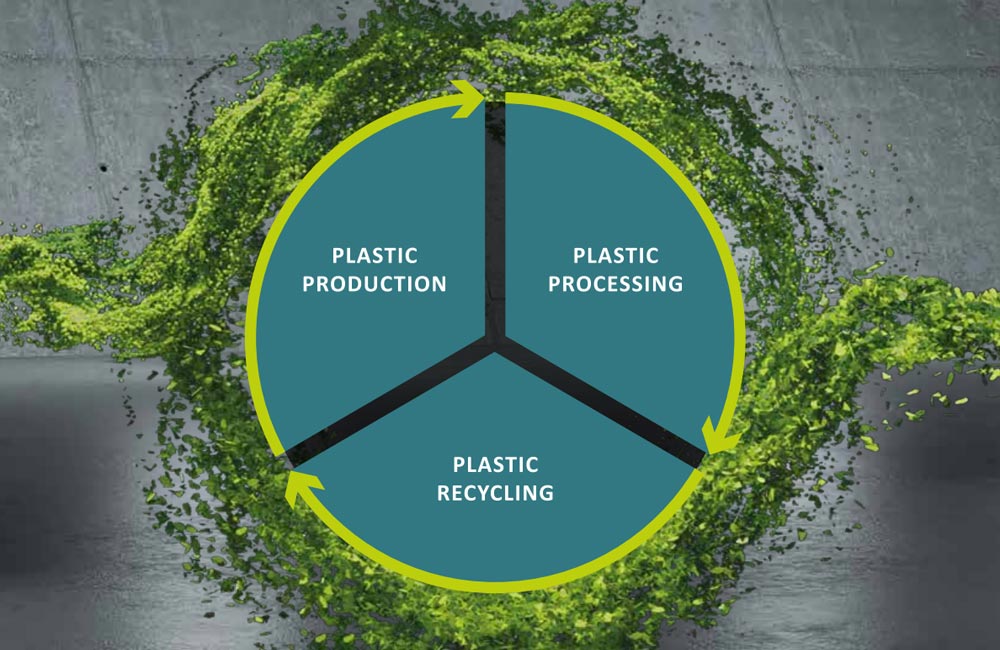

Circular Economy

May 19, 2020 |

How plastics processors use recyclates profitably

Why recyclates increase profitability

Recyclates have many advantages – for processors, consumers and the environment. Although the price of recyclates fluctuates, it is generally lower than the cost of new materials. There is also a long-term trend towards greater environmental consciousness in society at large, which make it more important that companies actively address environmental issues. Customers notice the proportion of recyclate materials used, and some even demand their use, so companies are increasingly committing to using certain ratios of recyclates.

Recyclates accounted for approximately 12.3% of the total volume of plastics processed in Germany in 2017. An industry comparison shows that significant quantities of recyclates were used in agriculture (34.9%), construction (21.5%) and packaging applications (9.1%).* That is a win for the environment, because using recyclates preserves resources. It is clear that the circular economy is becoming an important megatrend. But to make use of recyclates and truly close the plastic cycle, they have to be constantly available in sufficient quantities, and meet certain quality standards. That still isn’t always the case.

Why is quality testing necessary?

A closer look shows that there are many sources of impurities in delivered recycled goods. One reason is that today’s packaging and products are often made from various types plastic, in a variety of colours and a range of materials. Beverage bottles and their lids are often made from different types of plastic. And plastic soap dispensers usually have a metal spring. If the different materials are not correctly identified, separated and sorted in the plastic recycling process, then they are mixed and shredded, and end up in recyclates.

What is the potential impact?

If the recyclates are impure, it has consequences.

For example, foreign plastics can change the physical properties of products

made from recyclates. That has a negative impact on product quality, leading to

complaints. Incorrect colours result in discolouration, another reason for

complaints. Metal impurities are the most common type of contamination in

recyclates.

How can metal impurities be avoided?

Plastics processors must consider how metal impurities can be reliably removed from recyclates. Since metal is often hard to identify in product flows, that is a significant challenge. Metal particles are virtually invisible when mixed in with granulate. However, there are other ways to detect them.

Recognising and interpreting signs

Specific signs that recyclates contain metals include the constant clogging of screens in extrusion or injection-moulding machines with metals, or the need to regularly clear screen changers of included metal or melt.

Frequent blockages of injection-moulding tool channels by metal parts also indicate the presence of metals in the product flow. Metal inclusion in finished products is also a clear sign of contamination.

Implementing detection and separation

Plastics processors have a number of ways to prevent metal impurities. They can assess the quality of material from recyclers by inspecting incoming goods through the installation of material analysis and metal detection systems. Material analysis systems automatically examine and document the composition of incoming material, allowing the plastics processor to immediately determine and survey recyclate quality.

Installing metal detectors with integrated separating units at the start of the production process, and at other critical points, protects products and systems by removing metals. State-of-the-art detection systems can identify and separate even the smallest metal particles. That is decisive, because the smaller the particles that are detected and eliminated, the better the protection against damage and complaints.

Magnet separators are also used, but are not sufficient on their own – because they only remove magnetic metals. They cannot eliminate stainless steel and other non-magnetic metals, such as copper, brass or aluminium. A magnet separator should, therefore, always be used in combination with a metal detector – to sort out iron in advance and thereby relieve the burden on the downstream metal detector.