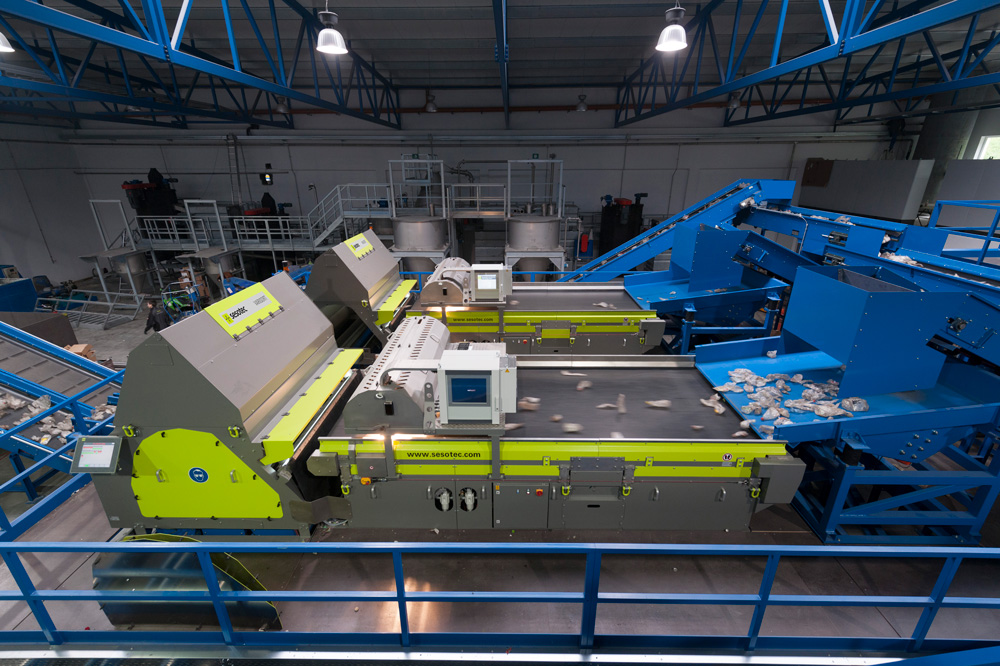

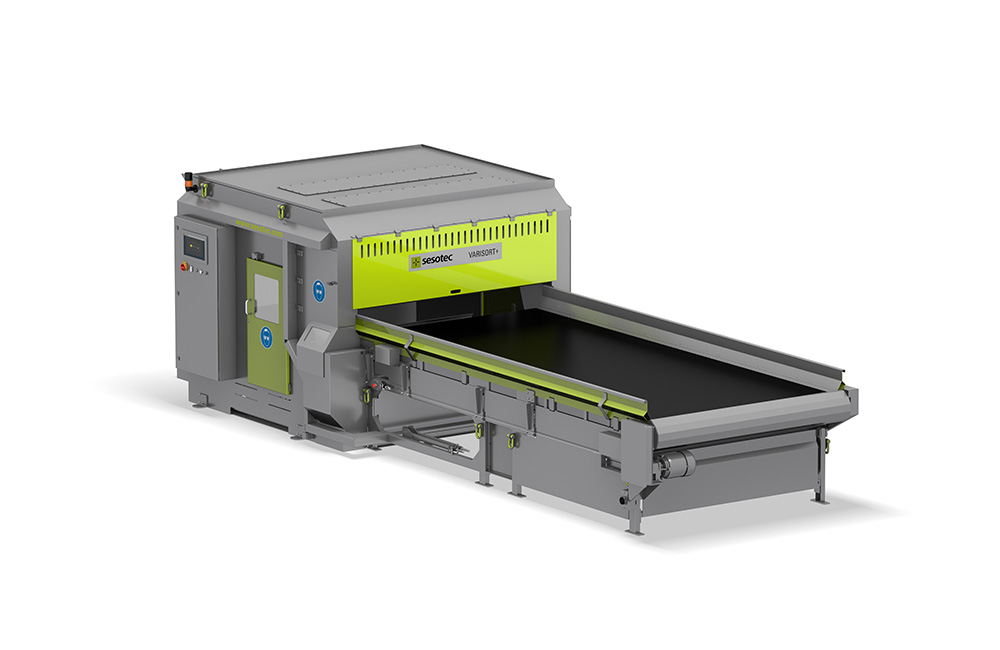

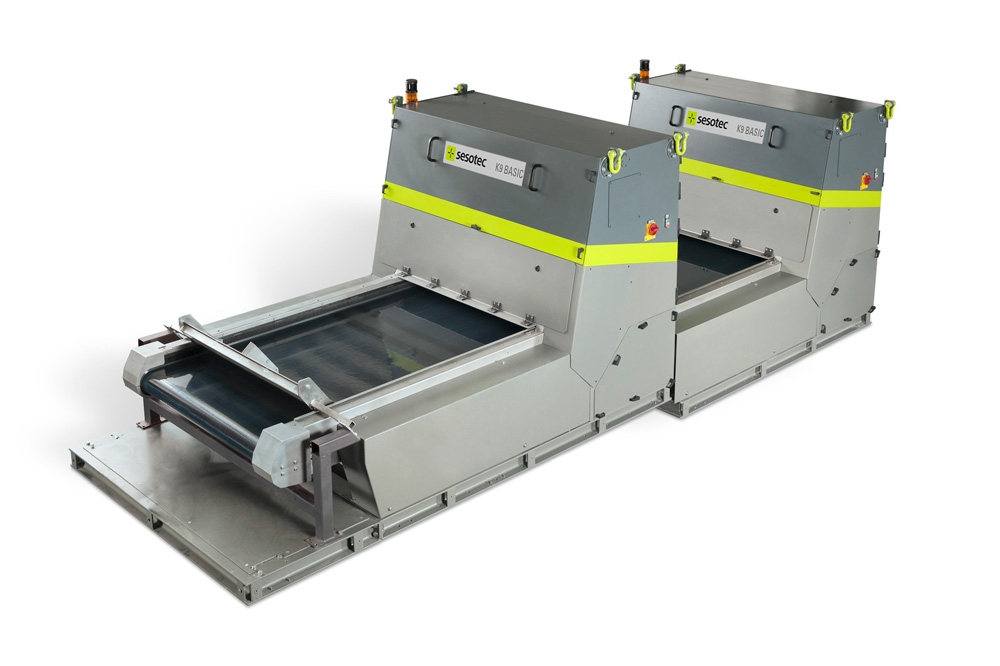

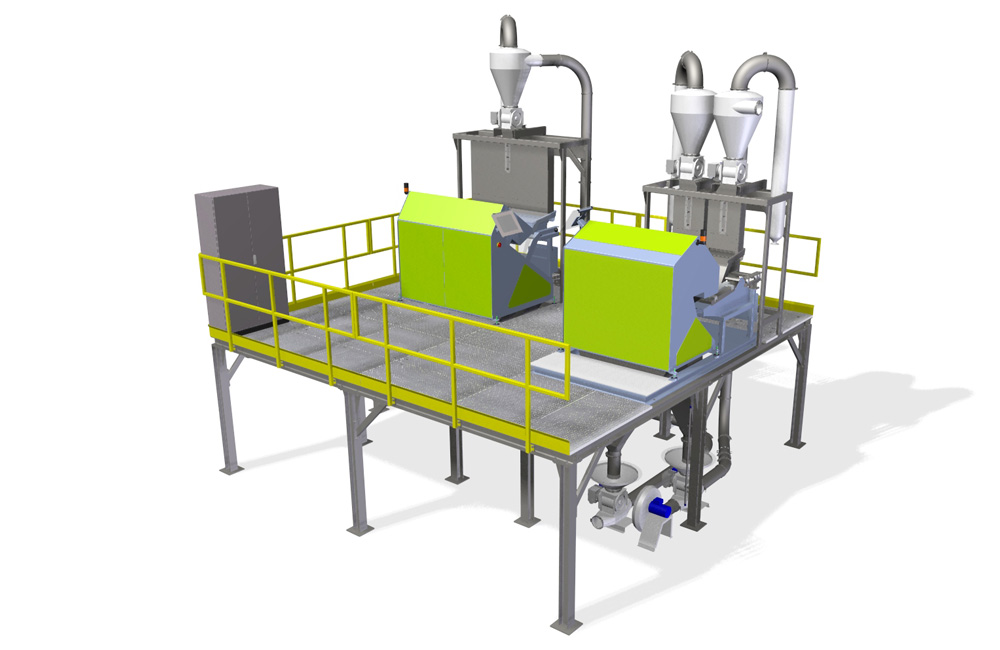

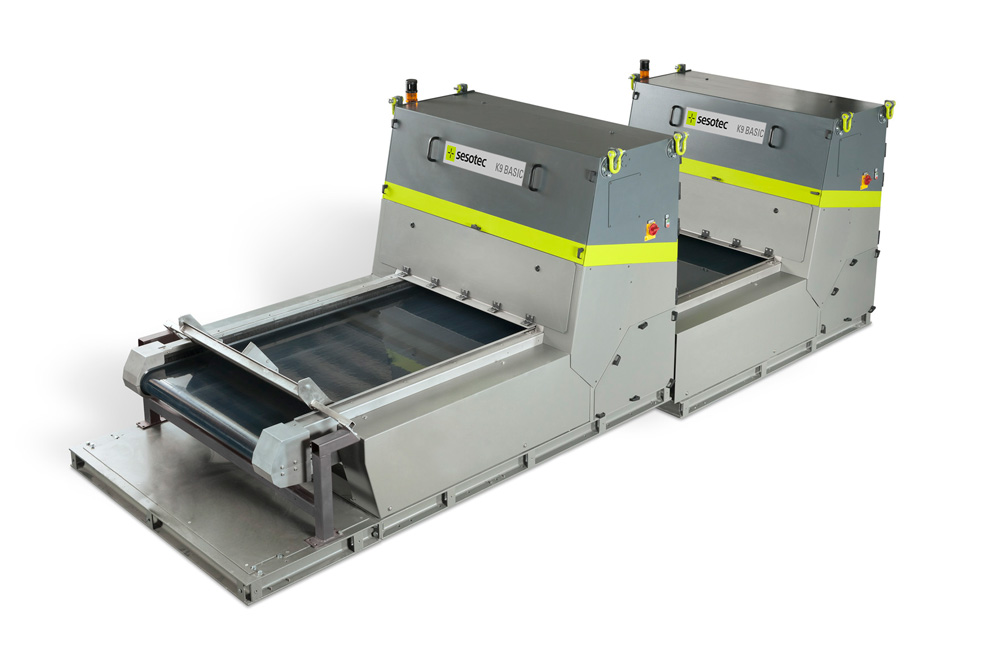

Alternative

system configurations for a wide range of applications

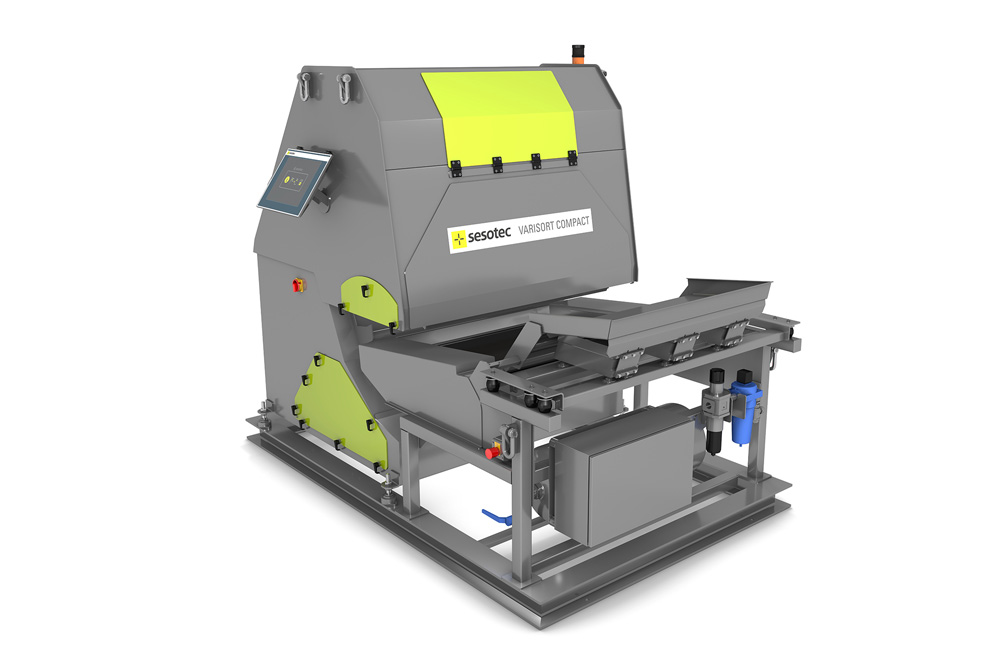

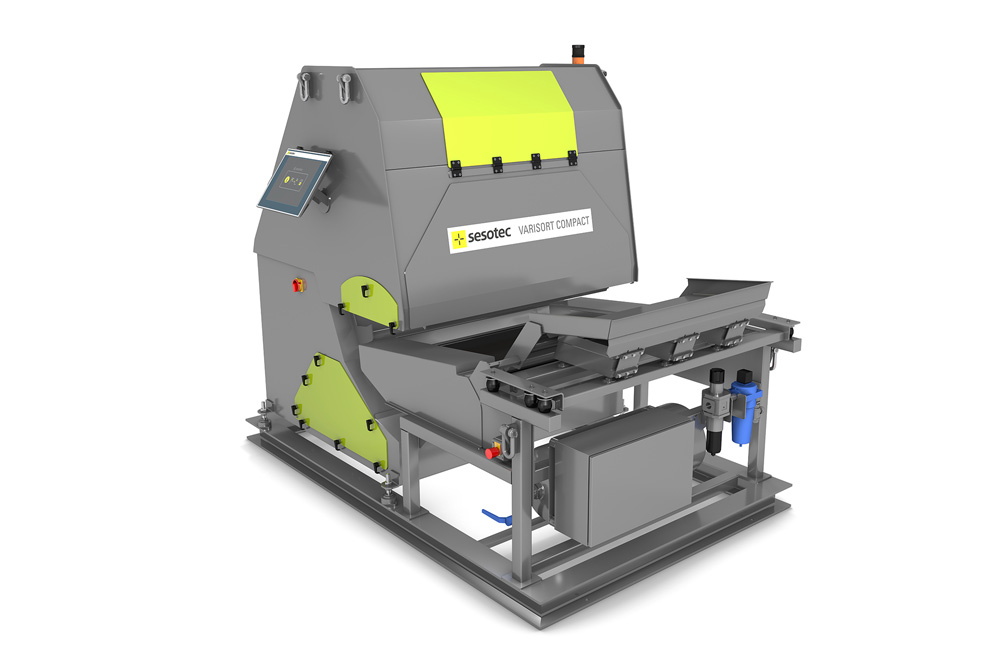

Multi-sensor sorting systems for various

recycling applications

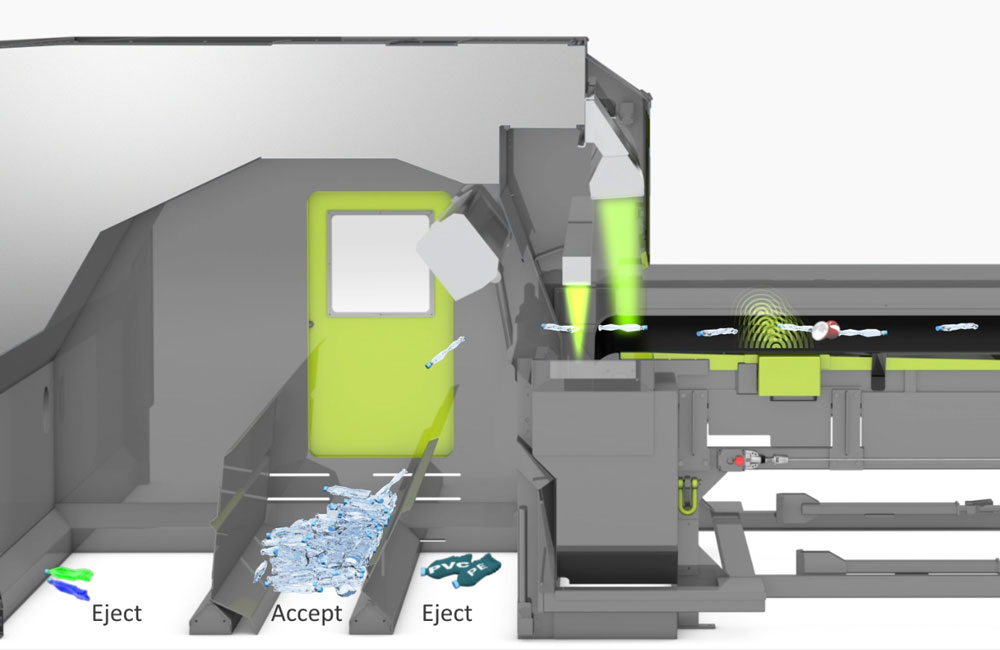

divide mixed material flows

into uniform fractions. The material (e.g. PET bottles, electrical waste, scrap

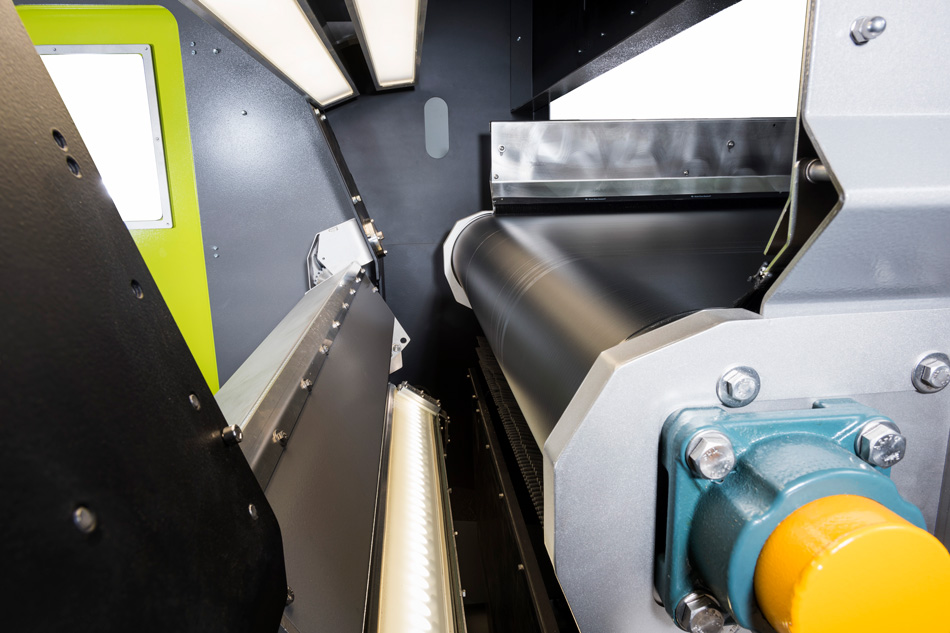

metal and household waste) reaches the detection area optimally scattered by

way of a fast-moving conveyor belt. Once there, sensors “scan” the material flow

based on color, shape and type of material. A metal sensor detects metals, with

optional detection of stainless steels as well. The electronic analysis

assembly then activates the air ejection unit with exact timing and

positioning, which removes the contaminants from the material flow.

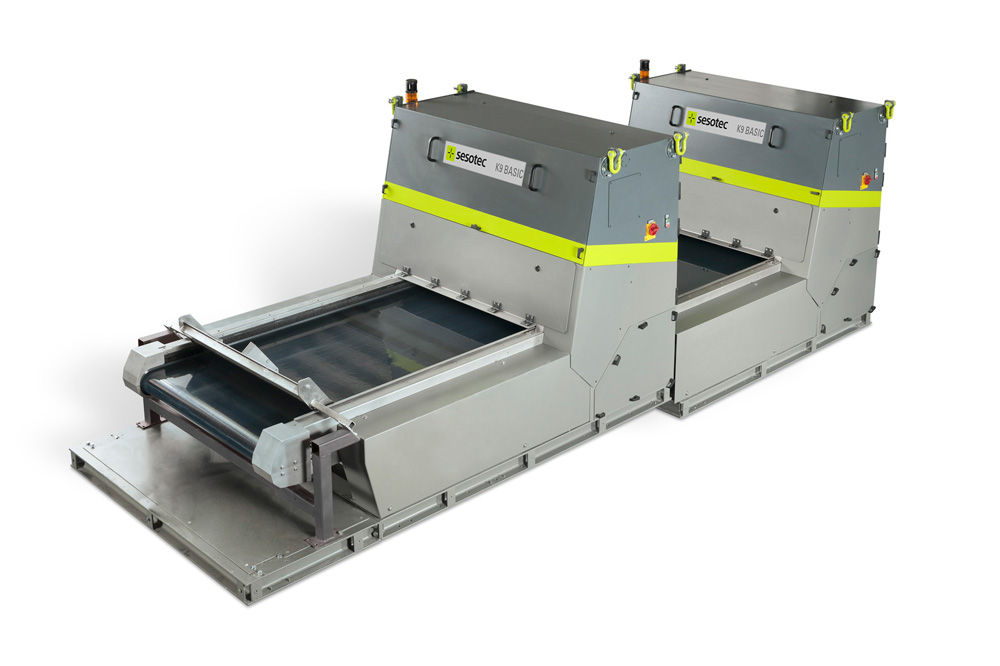

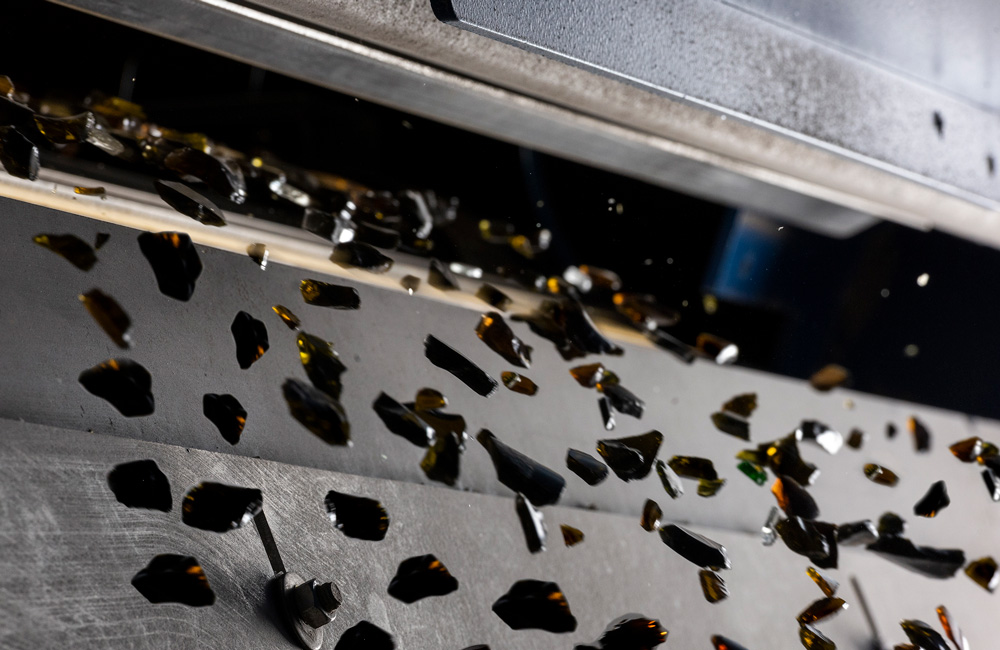

Conveyor belt sorting systems for recycling glass

separate

glass fragments by color and effectively remove foreign material, such as

ceramics, stones and porcelain (CSP), with reliability. They are also able to

achieve high-quality single-color fractions out of mixed-color glass fragments,

as well as detect and remove heat-resistant and/or special leaded glass.