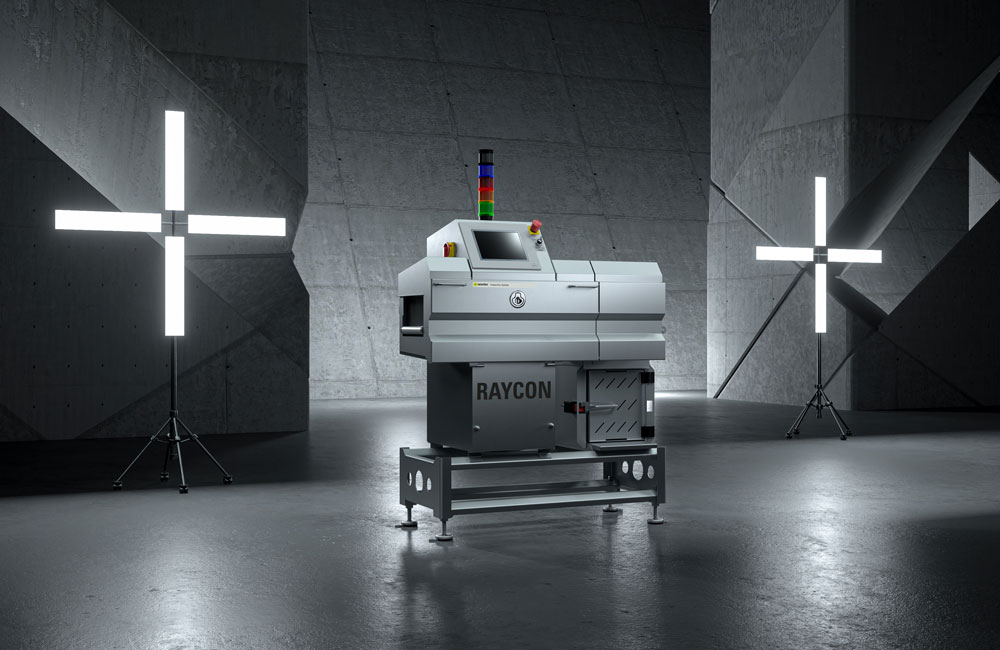

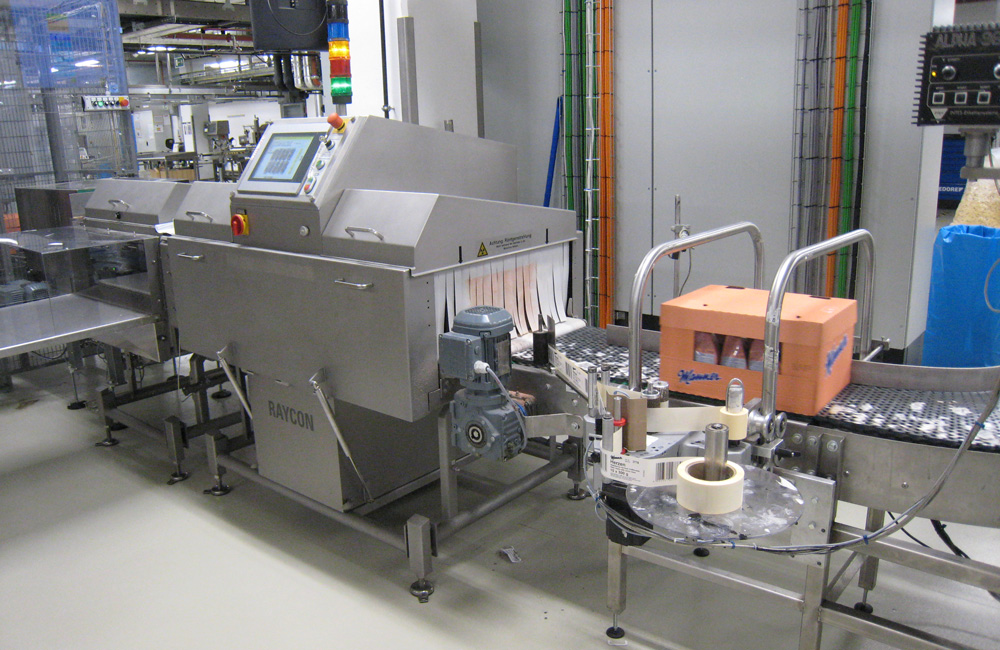

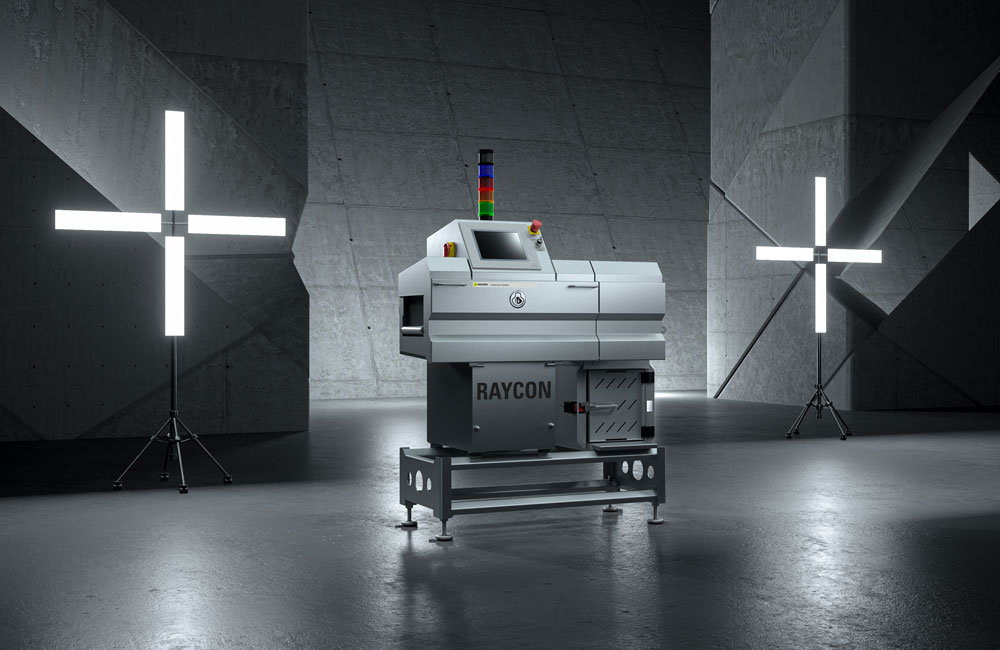

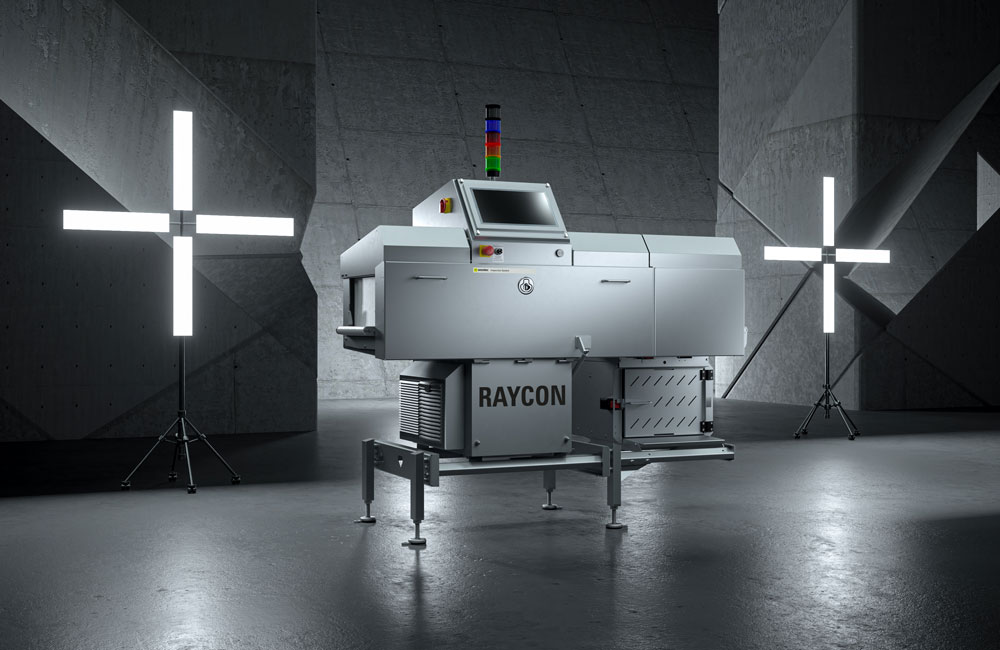

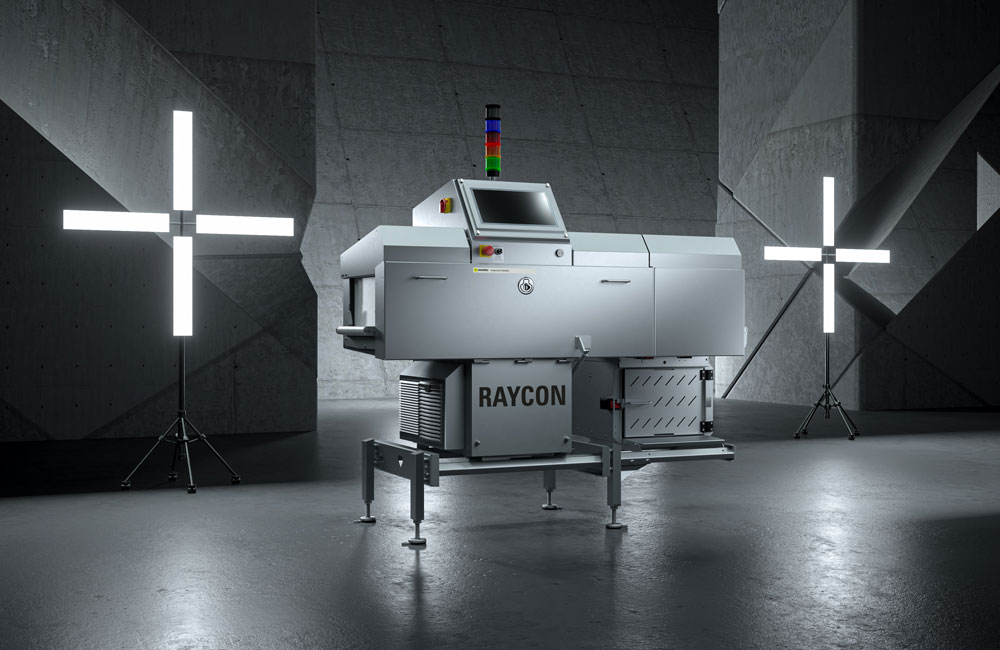

X-ray food inspection systems for packaged products

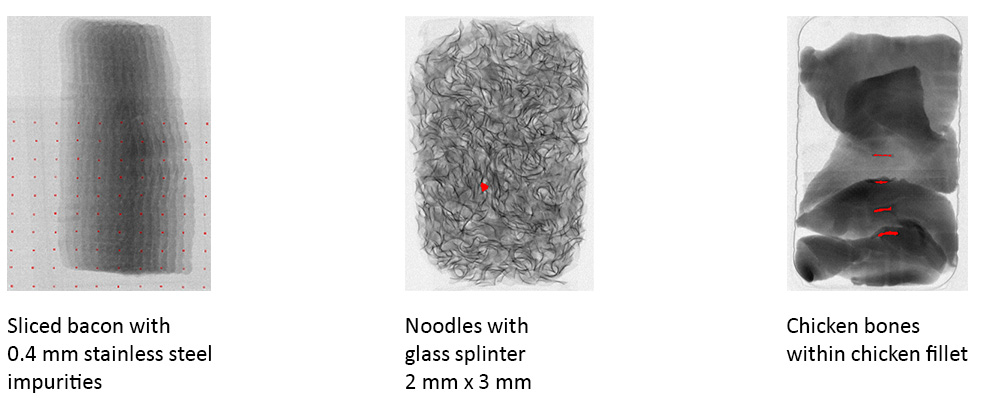

Our X-ray systems for packaged products are specifically designed for end-of-line quality control in the food industry. These X-ray food inspection systems combine highly efficient contaminant detection with the greatest ease of operation and a hygienic design, complying with all key food safety standards. Our X-ray inspection machines are especially well-suited for meat and other processed food products, as they not only detect metals, but also many other contaminants, including glass, ceramic, stones, bone fragments and PVC, not to mention a variety of product defects. All this combines to offer precise end-of-line inspection paired with reliable protection against customer complaints and recalls.

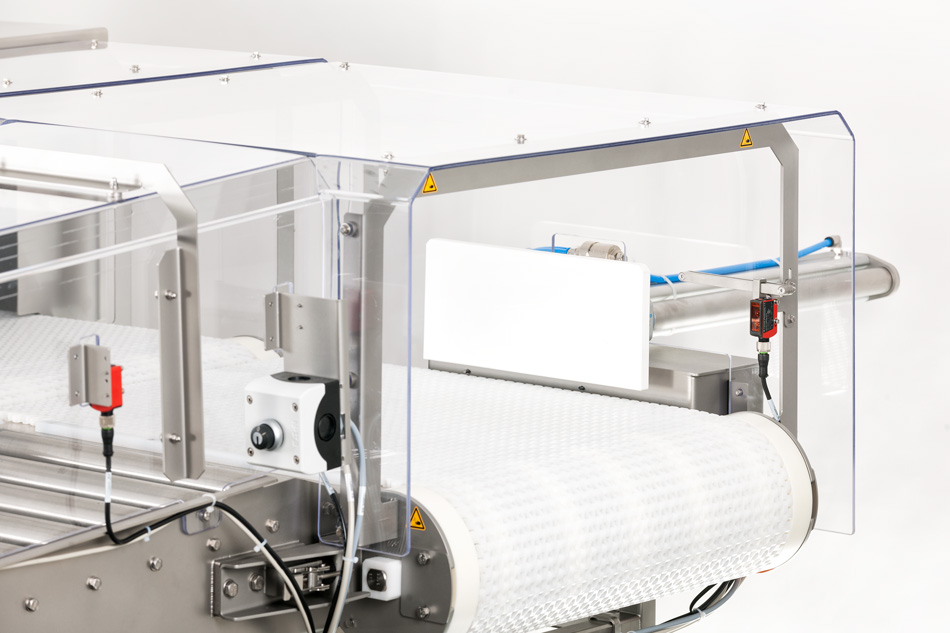

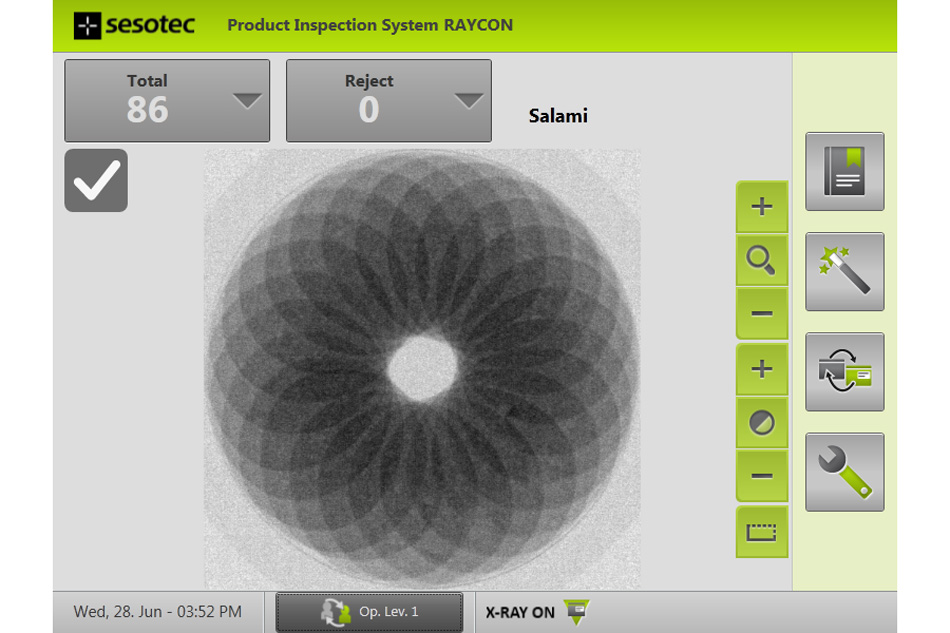

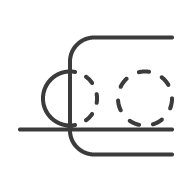

Packaged food products travel through the X-ray machine on a conveyor belt. By reading the X-ray signals, our special analysis software

creates a digital image of the product which it examines for contaminants and a variety of product defects, such as air bubbles, too much or too little weight, and

breakage. Integrated separation systems then ensure reliable removal of defective or contaminated products.