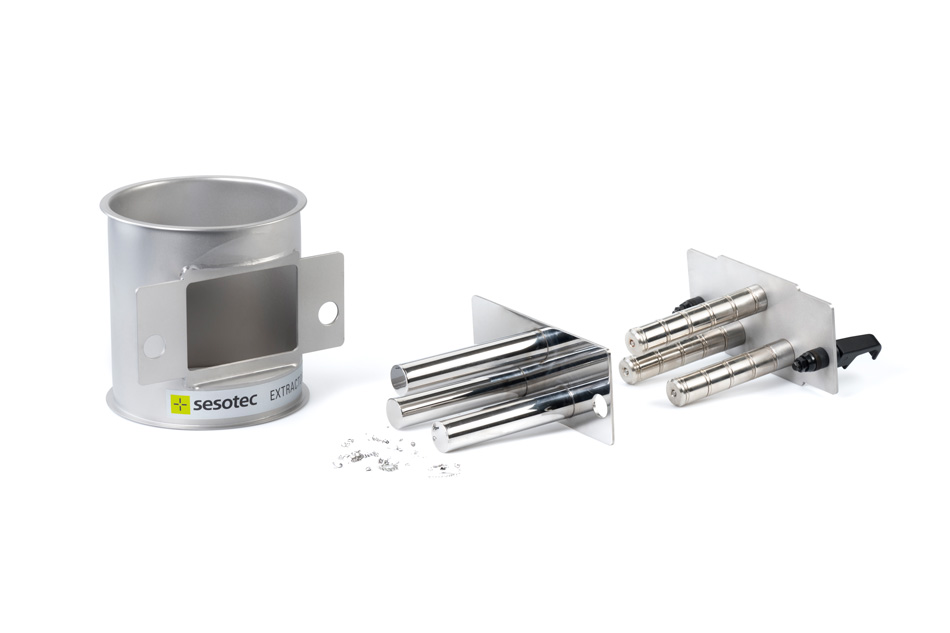

Magnet systems for material columns

Our magnet separators have been specifically designed for use in the plastics industry and can be integrated quickly and easily into columns of granulated material. They are installed shortly before or right in front of the material inlet of injection-molding machines, extruders and blow-molding machines, for example. By safely removing ferromagnetic particles, the separators provide highly effective protection against plant downtime and costly repairs.

Our magnet systems for material columns

integrate into piping systems, including existing ones. Once installed, they

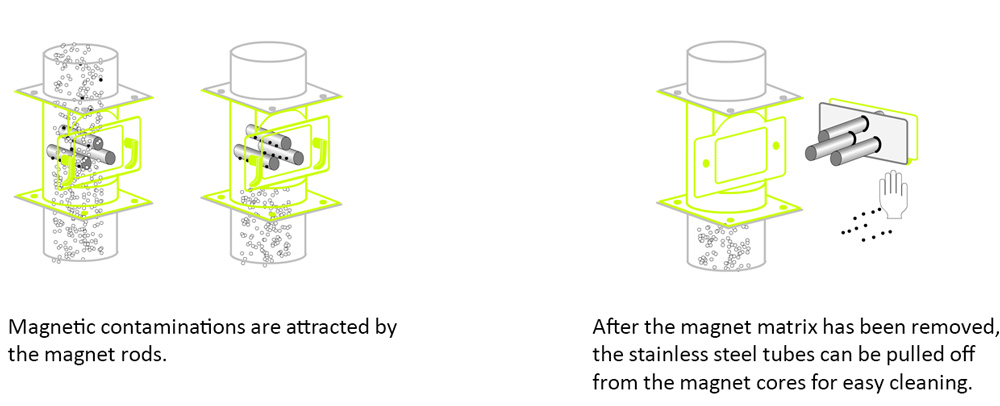

remove minute magnetic metal particles from the bulk goods that pass through. More

information on how Sesotec magnet separators work is available

here.