Design and alternative configurations

HRF technology

The special frequency of the detection signal

facilitates enhanced detection and the removal of ferrous and non-ferrous

metals, and even minute particles of non-magnetic stainless steel. The GENIUS+

and PRIMUS+ evaluation electronics offer the following:

- Digital

signal processing and quartz-stabilized detection frequency

- State-of-the-art

microprocessor technology with self-monitoring, self-calibration and

temperature compensation

- Product

compensation with auto-learn function

- Multi-product

memory for up to 240 products

- Password

protection

- EMC

combination filter to suppress external interference

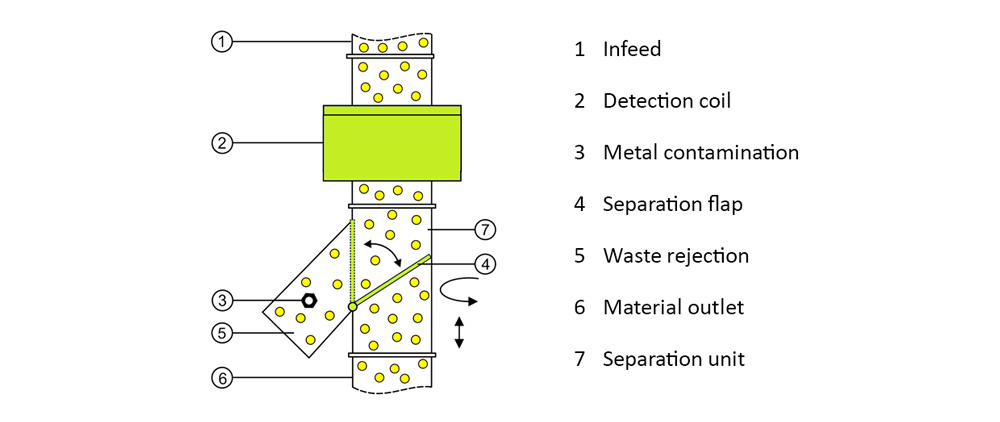

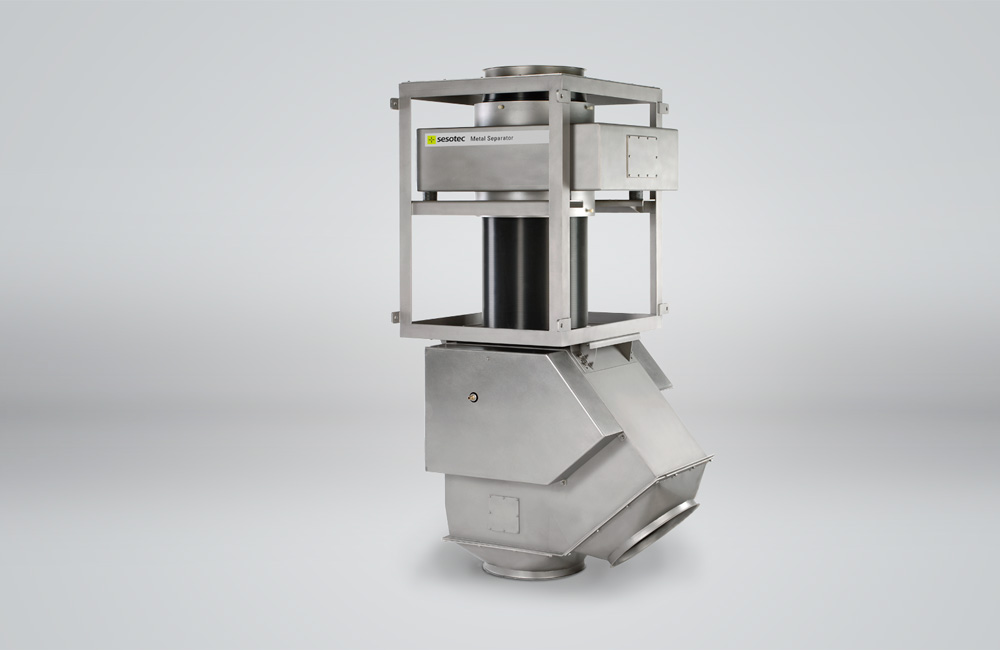

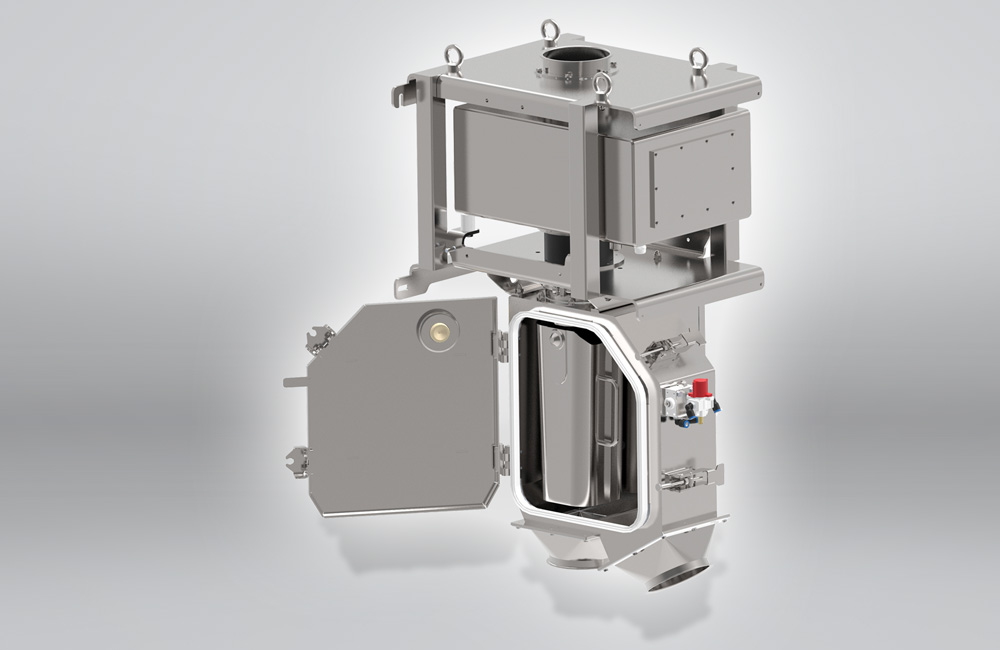

Different reject mechanisms

Apart from the standard reject mechanism, we

also offer a round version for the inspection of materials containing powder,

as well as a hopper-shaped alternative for the inspection of special materials,

or for special requirements relating to cleanability and wear protection. You can choose between different cleaning and

self-cleaning systems depending on the reject mechanism.

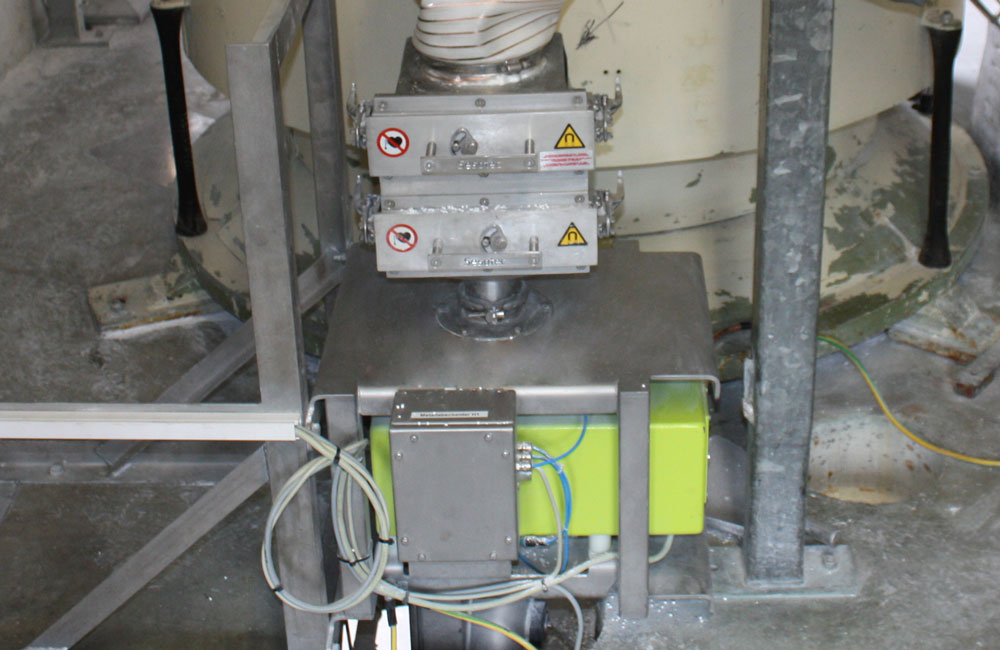

Self-monitoring

Our systems have visual and acoustic signaling

units, a digital event counter and a compressed-air monitoring system.

Customizable

The modular design makes it possible to adjust

the free-fall height and the position of the contamination outlet.

Special designs

When it comes to specialized applications, we offer a high-temperature

design, a special design for abrasive bulk goods and an ATEX-compliant version.

Products

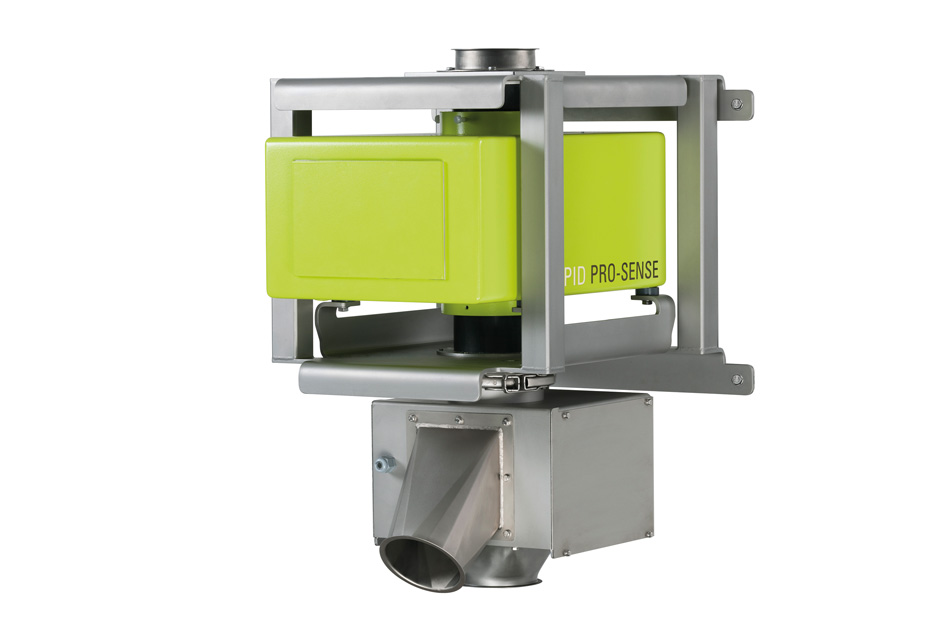

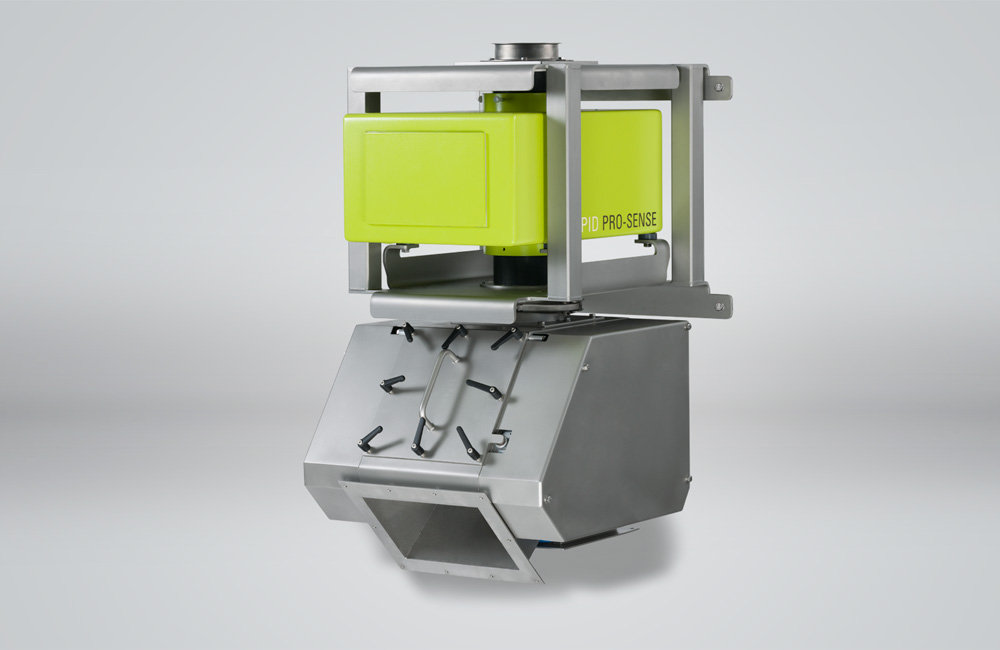

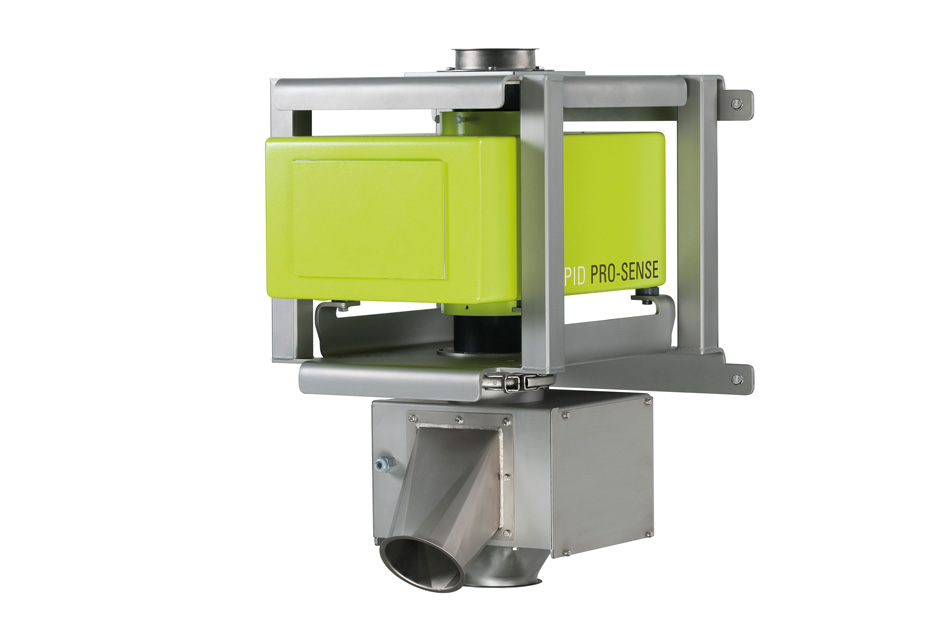

RAPID PRO-SENSE 6

High-performance metal separator forresin and compound manufacturers

Product Brochure

RAPID PRO-SENSE

High-performance metal separator for free-fall applications

Product Brochure

RAPID VARIO-FS

Metal separator for plastics applications

Product Brochure

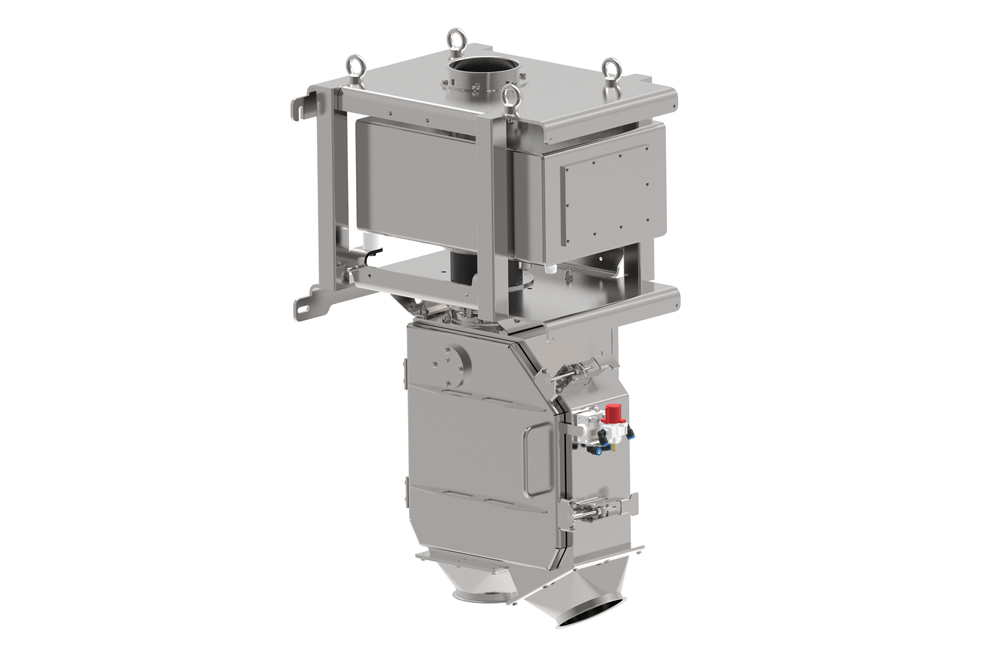

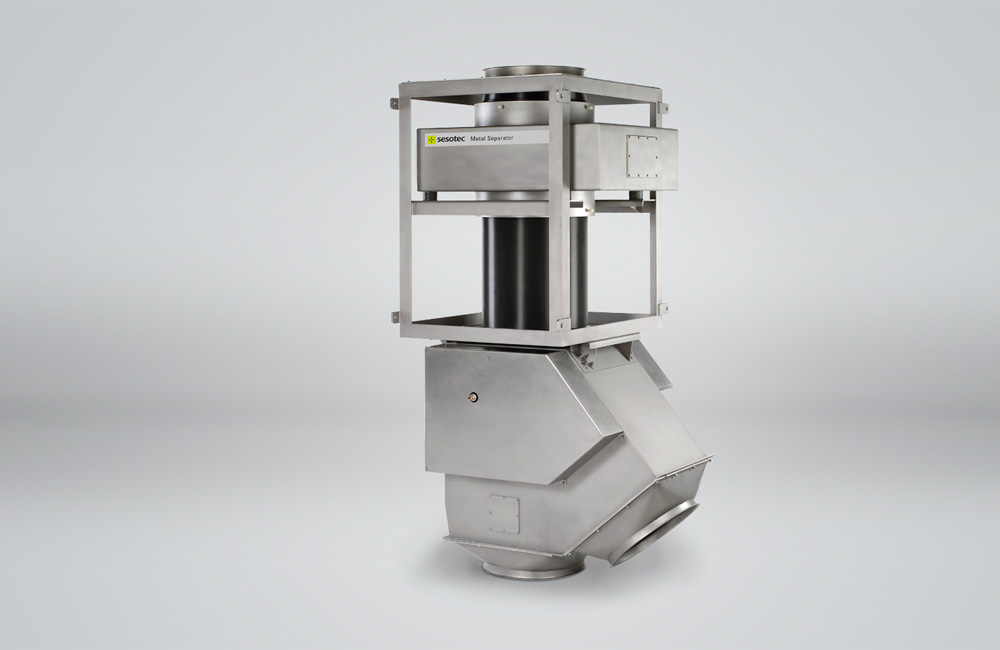

RAPID 4000

Metal separator for free-fall applications with low hygienic requirements

Product Brochure

RAPID 5000

Metal separator for free-fall applications with powders and fine-grained granulates

Product Brochure

RAPID 6000

Metal separator for free-fall applications with coarse-grained or flaky products

Product Brochure

RAPID 8000

Metal separator for free-fall applications with coarse-grained or flaky products and high hygienic requirements

Product Brochure