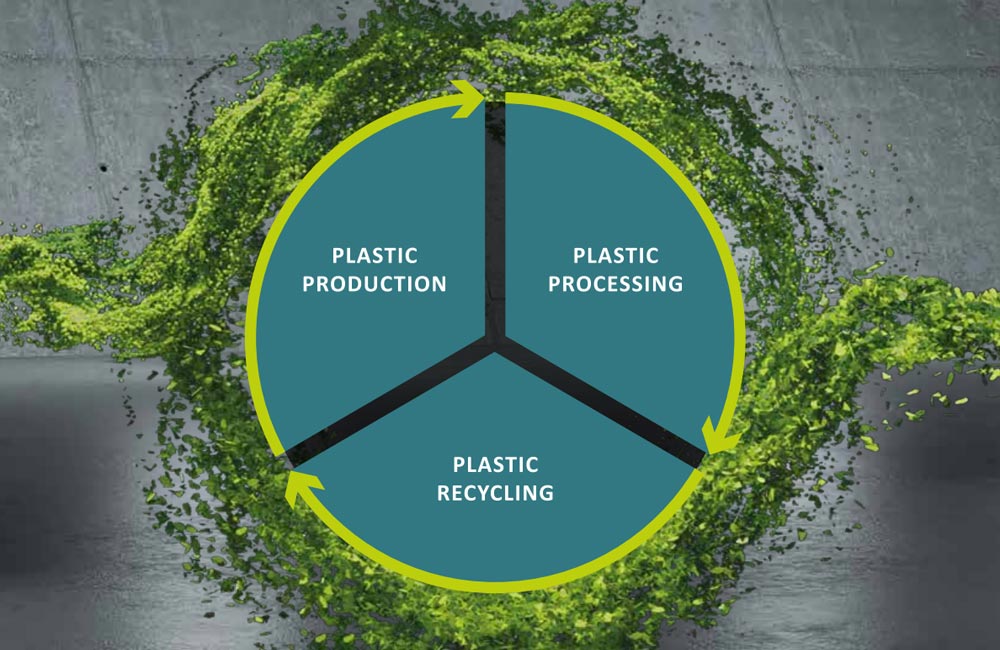

Circular Economy

Oct 16, 2023 |

Safe use of recyclates in the production of packaging and films

The production of packaging

Plastic packaging is manufactured using two different processes: The injection moulding process and thermoforming.

In the injection moulding process, also called injection moulding, the respective plastic material is liquefied (plasticised) and injected under pressure into a mould, the so-called injection moulding tool. Through cooling or a cross-linking reaction, the material in the mould becomes solid again and can be removed as a finished part after opening the mould. The cavity of the mould determines the shape and surface structure of the finished part. Injection moulding allows an almost free choice of shape and surface structure and is considered the most widespread process for the mass production of plastic parts of all kinds, not least because of its cost-effectiveness.

Thermoforming, often also referred to as deep drawing, is a process for forming thermoplastics under the influence of heat and with the aid of compressed air and vacuum. Depending on the production plant, the semi-finished plastic product is fed to the moulding machine in the form of a film (thin semi-finished product) or sheet (thick semi-finished product). In a heating station, the semi-finished product is heated on one or both sides, which softens it. The heated semi-finished product is carefully pulled apart to prevent sagging. In the mould station, it is fixed with the help of a clamping frame; a pre-stretcher and the thermoforming mould already provide a rough contour. Using compressed air from one side and vacuum from the other, the semi-finished product is pressed quickly and firmly against the water-cooled contour of the aluminium mould. Small holes or slits allow the air to escape between the semi-finished product and the tool. The cooled, now solid semi-finished product is separated from the moulding tool and then punched out.

The production of films

There are also two processes for the production of plastic films: Blown film extrusion and calendering.

In blown film extrusion, the raw material is first heated and melted in an extruder. Under pressure, the molten plastic mass is then forced through the extrusion head, a ring-shaped nozzle. A melting tube forms, which is inflated with air and simultaneously cooled by cool air from the outside. The plastic bubble expands and a thin plastic film is formed. During this phase of the process, the width and thickness of the film are determined. They depend on the size to which the tube is inflated. Once the tube of film has cooled, it is flattened by squeeze rolling and then automatically wound onto large rolls. Packaging films produced by film extrusion account for a significant proportion of the plastic packaging produced worldwide.

In calendering, the plastic material is also heated in an extruder and melted into a liquid mass. This molten plastic mass is then passed between two large, heated rollers, the so-called calender rollers. The distances between the calender rollers can be adjusted depending on the desired thickness of the film. The molten plastic mass is evenly distributed and compacted between the rollers. During this process, the rollers cool the film, giving it its final strength and surface structure. The finished plastic film is then pulled on a take-off device and wound onto large rolls.

Use of recycled materials in packaging and films

In recent years, the use of recycled materials in German packaging production has increased considerably. The reason for this, in addition to the increasing consumer demand for sustainable packaging solutions, is above all the legally prescribed minimum quota. The EU Commission and the Circular Plastics Alliance aim to use at least 10 million tonnes of recyclates in plastic products across the EU by 2025. The European Packaging Directive PPWD even recommends an anchored target of 55% physical recycling output, based on the market volume of plastic products. In line with this vision and the "Zero Granule Loss" initiative launched in 2019, the member companies of the industry association Kunststoffverpackungen e.V. has set itself the ambitious goal of increasing the proportion of recycled materials in plastic packaging to one million tonnes by 2025. The problem here is that the available raw material often has impurities - and plastics processors are faced with the challenge of still having to guarantee consistent product quality. Impurities that are common include:

- PVC: The use of PVC in products poses significant health risks as it can release hydrochloric acid at high temperatures. This is of particular concern when PVC is used in food packaging or films as it can pose health risks.

- Foreign colours: The addition of foreign colours can cause discolouration in the final product and affect quality.

- Metal impurities: Metal impurities are a serious hazard as they can cause significant damage to production equipment as well as have a negative impact on the final product. Even tiny metal particles can cause a strand of film to break, for example, or lead to other undesirable consequences. This can significantly affect the quality and safety of the manufactured products.

However, there are proven techniques to minimise or even eliminate the risks of machine damage, production stoppages or product recalls:

The use of sophisticated material analysis systems, for example, makes it possible to check and document the exact composition of the input material in advance to ensure that only high-quality material is used.

Innovative sorting systems are also capable of pre-sorting the input material as well as thoroughly re-sorting the scrap material again to keep the loss of good material as low as possible.

Metal detectors at critical points in the production process reliably detect and separate even the smallest metallic contaminants that could damage the production equipment.

Strict quality control and regular inspections with analysis systems are also crucial to ensure that neither PVC nor foreign colours enter the production process.

With the help of these technologies, it is possible to ensure that high product quality is maintained, while at the same time guaranteeing process reliability and avoiding potential problems. This automatically increases profitability, because they are effectively protected from expensive machine damage and production downtime, complaints and recalls. In addition, no valuable material is wasted.