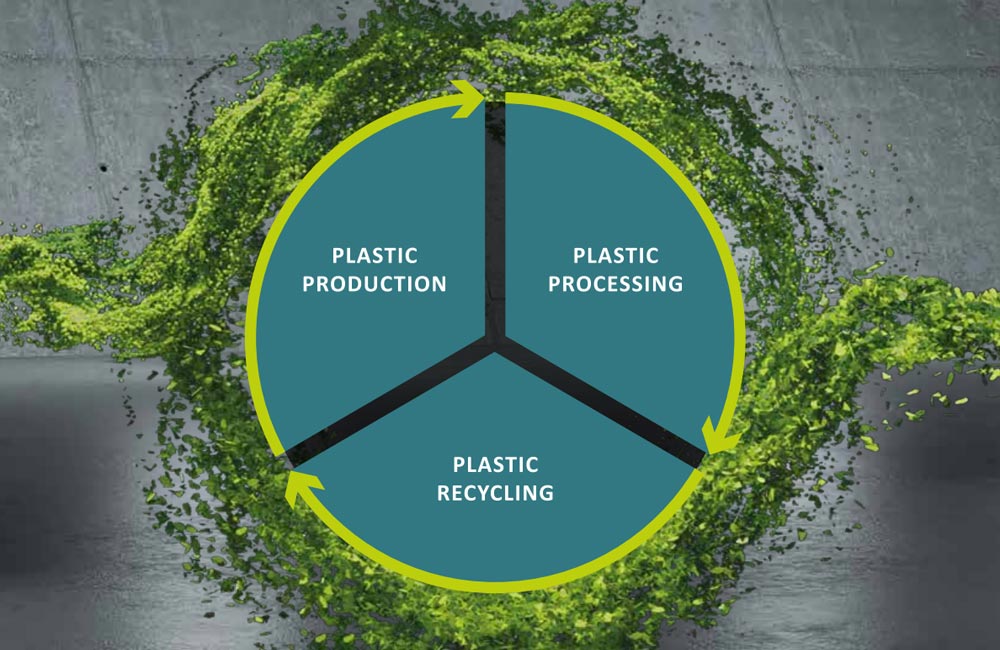

Circular Economy

May 09, 2023 |

Using recycled material in the production of preforms, blow-moulded parts and plastic bottles - how it works!

What is a preform?

A preform is an intermediate product that is blow-moulded or blown, into it’s final shape, typically a bottle or container in another manufacturing process. Preforms differ based on application with various size, weight, shape and colour; and are individually adapted to the customer's requiremens.

The most common form is a PET blank. A PET blank, also called PETling or PET preform, is the injection-moulded preform of the most commonly used PET bottle.

What is a blow-moulded part?

Blow-moulded parts are hollow components made of thermoplastic material, which are produced using the blow-moulding process. In this process, the plastics are first placed in a mould and then inflated under compressed air to obtain the final desired shape and size. This process can be done in a single stage, directly from raw material, or in a two stage process, utililzing premoulds as described above. The blow moulding process makes it possible to manufacture products in large quantities. The plastics most commonly used in this process are PE-HD, PP, PE-LD and PVC. Blow moulded parts are used in a wide variety of industries and including plastic bottles, canisters, fuel tanks, expansion tanks and wash water tanks.

The use of recycled materials in preforms, blow moulded parts and plastic bottles

The use of recycled material in preforms, blow-moulded parts and plastic bottles is an important contribution to the circular economy and sustainability. Not only legislators, but also customers are increasingly demanding the use of recyclates in the manufacture of new products. However, the market for high-quality recyclate is growing rapidly, which can make it more expensive when compared to virgin material. For this reason, many plastics processors buy lower-quality recycled material at lower prices in order to still be able to operate profitably. This makes it very important to carefully inspect and analyse the incoming material before processing. The better the quality of the raw material, the more efficient the further processing.

Furthermore,

contaminated raw material can have far-reaching effects if the impurities

remain undetected. If, for example, they leave residues in the recycled

products, this can lead to complaints, which means additional effort and costs

for the manufacturers. If the impurities are metallic foreign bodies, this can

result in severe damage to the production equipment. This results in

considerable costs and unplanned downtime for plastics processing companies.

Automatic

analysis systems enable a fast and thorough quality analysis of the input

material. However it is critical to use the appropriate inspection technologies

in the further processing stages. For users of equipment such as injection

moulding or blow moulding machines, continuous operation is enormously

important for profitability. In these applications even the smallest metal

parts can cause significant damage such as clogging melt filters, hot runners

and nozzle tools, blocking non-return valves or damaging plasticising screws

and cylinders. To avoid this, it is advisable to use metal detectors and

separators not only at the beginning of the process, but also at critical

points through production.

If any interfering materials are detected and discharged at the right time, this not only increases process continuity and productivity, but it can also prevent damage that could put the machine out of operation for days. By using the right process technology, plastics processors can not only buy and process recycled raw materials without risk, but also increase the profitability of their production.

Conclusion

Sustainability

requirements as well as increasing customer demands require an increased use of

recyclates in the manufacture of new products. However, plastics processors are

often faced with the challenge that not enough high-quality recycled raw

material is available and material that is available is of inferior qualities

to be processed. Precise control of the recyclate is therefore of great

importance in order to avoid contamination and ensure the highest quality of

the input material.

Additionally during the processing, the application of the

right process technology is crucial to ensure the protection of the equipment

throughout the entire production process. Innovative material analysis systems,

metal detectors with integrated separation units and recovery systems help to

achieve higher material efficiency and quality assurance of the end product. This

makes manufacturers of foreign object inspection systems important partners in

material processing and material efficiency.