Circular Economy

Apr 28, 2021 |

Recycling rate, recyclate content and the impact on the plastics industry

What is meant by recycling rate?

The recycling rate is the percentage of recyclable materials actually recycled from waste. A distinction is made here between secondary components (complete, recyclable components) and secondary raw materials. However, the exact reference figures used to calculate the recycling rate are as varied as they are controversial. This is because the recycling rate is often equated with the recovery rate. However, while the latter also includes the energetic recovery of valuable materials from waste - i.e. energy recovery through incineration and thus a waste of resources - the recycling rate excludes this type of recovery.

The Waste Management Act (Kreislaufwirtschaftsgesetz – KrWG) defines recycling in Article 3 (25) as “any recovery operation by which waste is reprocessed into products, materials or substances either for the original purpose or for other purposes”. It also states that recycling excludes “energy recovery and reprocessing into materials intended for use as fuel or for backfilling” (23a).

According to the study Plastics Material Flow Diagram in Germany 2019, 99.4% of the total 6.3 million tons of plastic waste in this country is recovered, but only 47% is recycled. In fact, only 33% of plastic waste from private households is recycled. The reason for this discrepancy is that plastics in industry are mostly clean and sorted by type, but in households they are heavily mixed.

Among other things, the proper separation of waste by consumers is important here, because mixed waste is difficult to recycle. The better it is separated at home, the easier it is for different types of packaging to be sorted in the plants and consequently recycled.

EU Waste Framework Directive

In order to increase the recycling rate for municipal waste, the EU

Waste Framework Directive of 2008 was strengthened again in 2018. While the

original directive stipulated a recycling rate of 50% for certain materials for

each country by 2020, the amended Waste

Framework Directive (Directive (EU) 2018/851) stipulates 55% by

2025, 60% by 2030 and even 65% by 2035. The calculation of the recycling rate

has also changed with the new EU requirements. Up to then, the EU member states

used “input calculations” as their guideline. This means that what is recycled

from a collection system is counted. In the future, output-oriented quotas will apply throughout the

EU. This means that only waste that is actually recycled will be counted as

recycled.To ensure uniform application of the calculation rules, the EU

Commission has defined specific calculation and measurement points for the most

common wastes and recycling processes.

How has the recycling rate for plastics developed in recent years?

In 2019, 6.28 million tons of plastic waste were generated in Germany. Around 85.2% of this waste was generated after use (“post-consumer waste”). The remaining 14.8% was generated during the production and, above all, the processing of plastics. That sounds like a lot of recycled material. But far from it. As shown in the Plastic Atlas published by the Heinrich Böll Foundation in 2019, 60% of our plastic waste is “combusted with energy recovery”. The nearly 40 percent remaining is recycled.

Development of plastic packaging recycling

According to IK Industrievereinigung Kunststoffverpackungen e.V., there has been a clear positive trend in the recycling rates of plastic packaging since the German Packaging Act came into force in 2019. According to a study conducted by GVM Gesellschaft für Verpackungsmarktforschung, they rose by 12.3% in the sector of end consumer use in 2019. As a result, in 2019 plastic packaging rates total 55.2%, based on the overall market. Thus, according to the Zentrale Stelle Verpackungsregister (Central Agency Packaging Register – ZSVR), the very ambitious statutory recycling rate of 58.5% was nearly achieved.

IK Managing Director Dr. Isabell Schmidt is pleased with this development: “The surge in recycling is a terrific success of the new packaging law that our industry has championed.”

At the same time, Schmidt emphasized that the circular economy must now continue to pick up speed and that it is now a matter of strengthening the financial incentives for recyclable packaging design so that investments in new packaging designs also pay off for everyone. A renewed review of the Packaging Act is planned for 2022.

What is meant by recyclates?

The

term “recyclate” is primarily used in the plastics industry and is

synonymous with reprocessed plastic waste. Recyclates are obtained by means of

different reprocessing methods depending on the condition of the plastic waste

being recycled. Plastic recyclates are generally divided into two categories:

“post-industrial recyclates” and “post-consumer recyclates”.

Post-industrial recyclates

Post-industrial recyclates are obtained from industrial waste that is generated as rejects during the production process. In most cases, they are of a single type and can therefore be crushed and recycled with the help of special plastic mills without any major sorting or cleaning effort. Post-industrial recyclates are of particularly high quality due to their clean starting material and are therefore preferred by many companies. And yet there are areas of application, such as food, cosmetics and pharmaceuticals, in which even the single-variety post-industrial recyclates may not be used, or may only be used to a limited extent, due to the most stringent requirements for product safety and hygiene.

Post-consumer recyclates

These recyclates are recovered from end consumer waste, i.e. the yellow sack or garbage can used in Germany. Post-consumer waste is collected, sorted by type of plastic (PP, PE, PS), shredded, washed and then melted into plastic granulate. Since the yellow sack contains packaging mixed from a wide variety of plastic types, processing it into high-quality recyclate is more demanding and requires state-of-the-art recycling and sorting facilities.

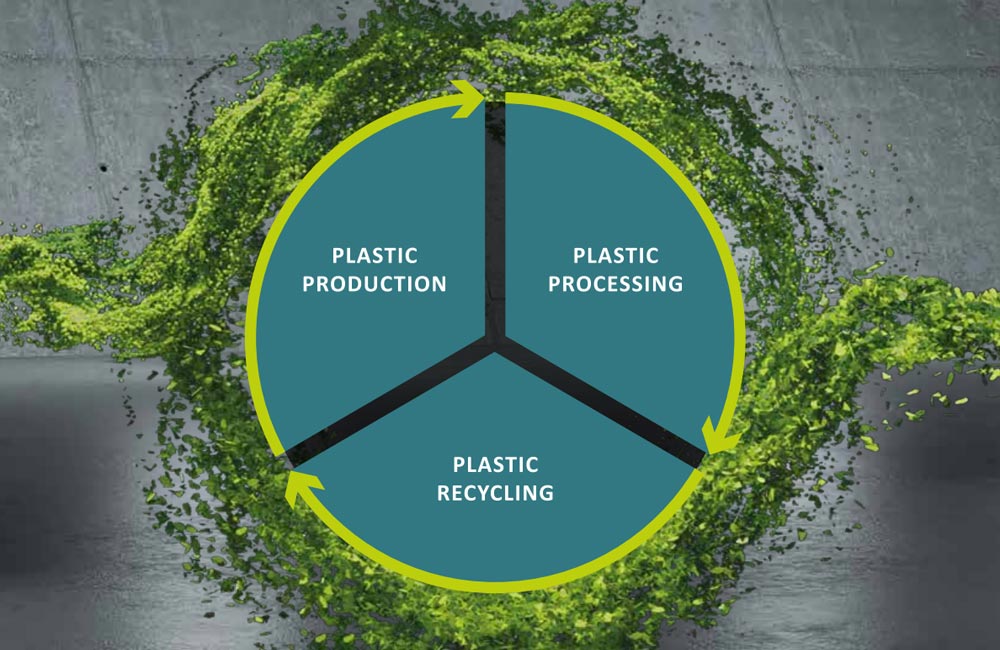

Sesotec supports all industrial areas of the plastics cycle with innovative solutions -

for more profitability, quality and productivity.

Discover our Circular Economy Systems.

Development of recyclate content and the consequences for the plastics industry

Recyclates are becoming increasingly important as a raw material for new plastic products. This was also demonstrated by the Plastics Material Flow Diagram in Germany published in 2019. In 2019, 13.7% of the total volume of plastics processed was covered by recyclates. Since the last survey in 2017, the volume of recyclates has increased by around 5% per year. However, there is still considerable room for improvement in the use of recyclates.

The IK (Industrievereinigung Kunststoffverpackungen), the German Association for Plastics Packaging and Films, sees the main obstacles to the use of recyclate in the lack of availability and, in some cases, inferior quality of the recycled material. Recyclers and waste disposal associations have therefore been calling for political action since the middle of 2020. Baden-Württemberg’s Minister of the Environment, Climate Protection and the Energy Sector, Franz Untersteller of the Green Party campaigned for a “mandatory percentage of recyclate content in plastics” at the Resource Efficiency and Circular Economy Congress held in Stuttgart. The Bundesrat (Germany’s upper house of parliament), however, rejected the call for national recyclate use quotas for certain products. The reason: While plastic recyclates are already routinely used in many sectors, such as construction, packaging and agriculture, the hurdles are very high in other sectors, such as food and cosmetics packaging, which place special demands on the quality of the recyclates. The required quantities and qualities of secondary raw materials are not currently available for such sensitive applications.

However, the quality and safety of products must under no circumstances be compromised by the use of recyclates. According to the IK, optimized waste separation by consumers plays a key role on the one hand, while on the other hand investments in high-tech sorting and high-quality processing are needed to cope with the required volumes and to sort them optimally. Only through the smooth interaction of all parties involved – from consumers and recyclers to manufacturers and processors – can a stable market for recyclates be established in the long term.

Challenge for recyclers, manufacturers and processors of plastic

The increasing demands on recyclate quantity and quality are not only increasing the pressure on recyclers to produce more single-variety material. Manufacturers and processors must also use more recyclate in order to be able to meet customer demands and legal requirements in the future. On the one hand, some machines have to be retrofitted in order to be able to process more materials, and on the other hand, state-of-the-art material analysis systems, sorting equipment and metal separators are required in order to be able to handle lower-grade qualities and reliably remove any impurities.

Conclusion

The terms recycling rate and recyclate content are often used synonymously but have different meanings. While the recycling rate represents the proportion of waste that is recycled, recyclate content is the proportion of secondary raw materials that are incorporated into new products. Both recycling rate and recyclate content are important factors for a functioning circular economy.

However, the recycling rate is difficult to track. Up to now, everything that goes from a sorting plant to recycling has been calculated. Losses in the recycling process, such as the incineration of impurities, have so far been included in the official quota. However, the recycling rate directly determines the availability of secondary raw materials. The more material is recycled, the more material is available for the production of recyclate. To get the cycle going, the recycling rate and thus the use of recyclates in the manufacture of new products must be significantly increased. This requires both further political action and the willingness of everyone involved, whether consumers, recyclers, manufacturers or processors, to make their contribution and pull together.

New E-Book: The Circular Economy - Challenges and opportunities for Recyclers and plastics processors

In this comprehensive e-book, you will gain insight into the most important factors of the Circular Economy. In particular, we look at the goal of creating a circular economy that must be profitable not only for people and the environment but also for recyclers, plastics manufacturers and processors.