Circular Economy

Dec 22, 2021 |

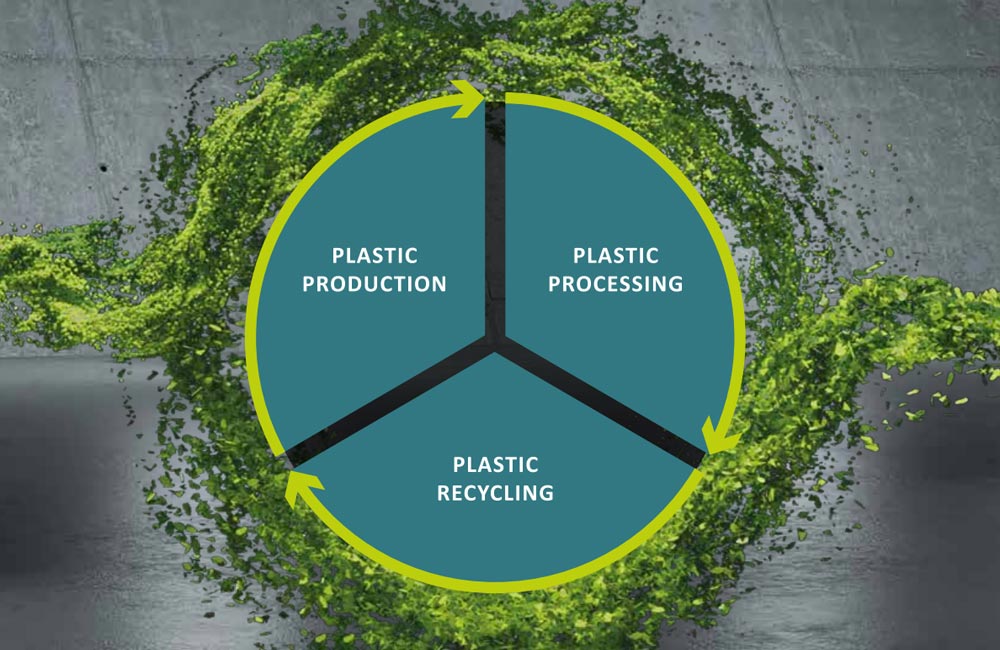

Design for recycling - an important component of the Circular Economy

What does it mean to design for recycling?

Packaging is a crucial part of modern life. It protects products and communicates important information to consumers. However, most packaging is disposed of after a single use. As such, a tremendous volume of valuable materials end up in the trash.

To put post-consumer packaging to use and close the loop, it is essential to consider the recyclability of packaging materials as early as the design stage. In fact, some legislation requires that packaging is designed in a way that facilitates recycling. For example, the EU Circular Economy Action Plan and the German Packaging Act lay out ambitious goals and targets: by 2030, all packaging produced in the EU must be 100% reusable or recyclable.

Why is it more important than ever to design for recycling?

Produced, used briefly, and immediately thrown away: the use of plastic packaging is steadily increasing – and so is the volume of plastic waste. In order to achieve a sustainable economy and protect our environment for future generations, our relationship with plastic must fundamentally change. After all, used plastic is not necessarily waste. Rather, it is a valuable source of raw materials that has gone largely untapped up to this point.

According to the study “Burning Questions – Pathways to a circular plastic packaging system in Germany ” (de. Verpackungswende jetzt!) by the WWF, 89% of all plastic packaging is made from virgin materials and 50% of all plastic waste is incinerated after a single use. In order to establish an effective and resource-efficient circular economy, plastic packaging should not be destroyed after use, but rather systematically and effectively reused and recycled.

All levels of society are grappling with the challenge of plastic waste: from policy makers, to manufacturers, to the recycling industry, to retailers, to consumers. An important instrument for overcoming this challenge is recycling-friendly design for plastic packaging, which would increase the yield and value of recycled materials.

According to industry experts, it would be possible to convert as much as 90% of multilayered plastic packaging to monolayer material without any loss in performance. This would result in an 11% greater yield in a closed-loop recycling system.

In the case of composite materials, many sorting systems cannot adequately separate the individual material layers. This means that many of these materials are not recycled, or that the recyclate they produce is of poor quality. If adjustments were made to the polymers, inks, adhesives, additives, and closures used in the production of plastic packaging, the yield and value of recyclates would see tremendous improvements.

The most important characteristics of

recycling-friendly design

Which criteria must be fulfilled in order for new packaging to be truly recycling-friendly? Since the introduction of the Packaging Act, the Central Packaging Register Office (ZSVR) has served as an enforcing authority in Germany. Every year, they publish the latest version of their minimum standard for determining the recyclability of packaging subject to system participation pursuant to section 21 (3) VerpackG. This document contains the minimum criteria that packaging must meet in order to be classified as recyclable, as well as an explanation of which materials are particularly suitable for inclusion in the material cycle and which are not.

According to the Packaging Act, all packaging must be made according to a sorting and recycling plan that allows the individual components to be sorted by material. If individual packaging components are made of different materials, they must be sortable and separable from one another. In addition, the packaging must not contain any substances that represent recycling incompatibilities, which could prevent recyclers from being able to reclaim the material.

Manufacturers are faced with a number of challenges in redesigning their packaging in order to meet future legal requirements:- Material

Packaging made from multiple layers of material quickly becomes a problem for recycling. Such packaging cannot be separated after use, and thus must be assigned to a single material fraction at the recycling facility. For this reason, manufacturers should switch to mono-material packaging wherever possible or use easily separable materials. Closures should ideally be made from the same material as the rest of the packaging. -

Color

/ Print

If packaging is not correctly identified by the sorting machine, it is automatically ejected from the system and will not be recycled. This is especially common in the case of dark colored packaging. For this reason, packaging manufacturers should use light or transparent colors, keep printing on the surface as small as possible, and avoid metallic effects. Heat-resistant inks and adhesives also pose problems in recycling. Water-soluble alternatives offer a solution to these issues. -

Labels

/ Banderoles

When sorting systems scan packaging in order to determine the material type, especially large labels made of materials that are different from the packaging can lead the machine to incorrectly identify the packaging material. As a result, the packaging may be assigned the wrong material type, thus detracting from the purity of the material fraction, or the packaging may not be recycled at all. To prevent such issues, packaging manufacturers should either avoid using labels entirely, or use labels made from the same materials as the packaging. Water-soluble or easily detachable labels are a promising solution here. -

Product

residue

Leftover product in or on packaging, such as detergent or wall paint, can not only complicate the recycling process, but it can also significantly detract from the quality of recyclate. Packaging manufacturers should design their packaging such that it is especially easy to empty and clean, for example with smooth inner surfaces and wide openings.

Conclusions

The transition from

a linear to a circular economy for plastic packaging is of utmost urgency,

especially with regards to environmental impact. Recycling-friendly packaging

is also environmentally friendly packaging. It simplifies collection, recovery,

and recycling; it reduces the volume of plastic waste and CO2 emissions; it

saves costs and can be converted through a closed-loop system into a

high-quality secondary raw material.

New E-Book: The Circular Economy - Challenges and opportunities for Recyclers and plastics processors

In this comprehensive e-book, you will gain insight into the most important factors of the Circular Economy. In particular, we look at the goal of creating a circular economy that must be profitable not only for people and the environment but also for recyclers, plastics manufacturers and processors.