Plastics

13/11/2024 |

New brochure - Product inspection in plastics production & processing

Sesotec GmbH, a leading supplier of foreign object detection and sorting systems, is presenting a new brochure. The 64-page booklet provides future-proof answers to the challenges facing the plastics industry - from increasing efficiency and process reliability to ensuring consistent product quality.

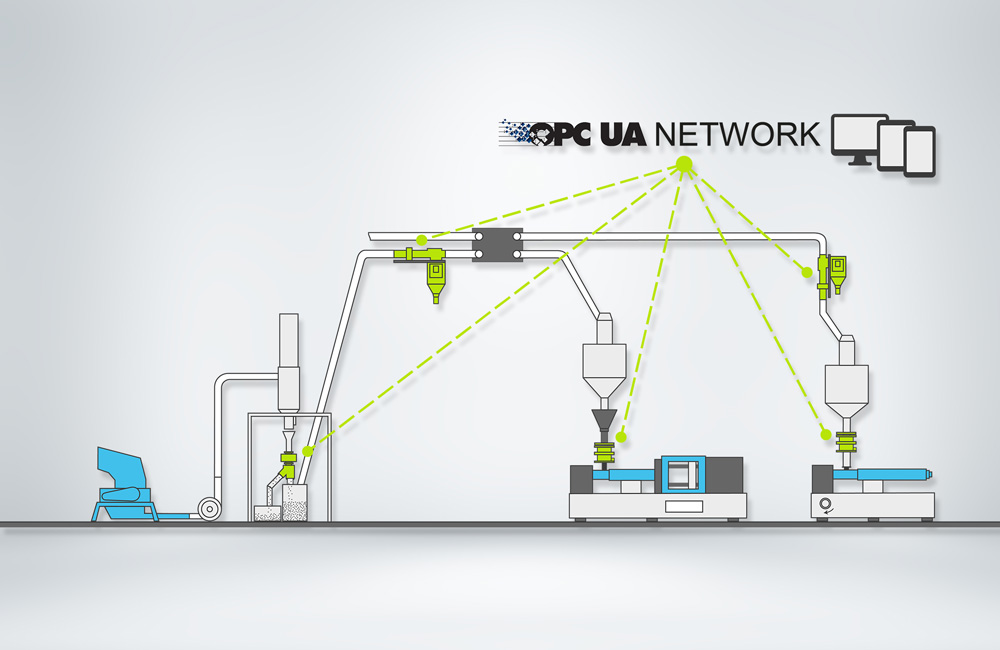

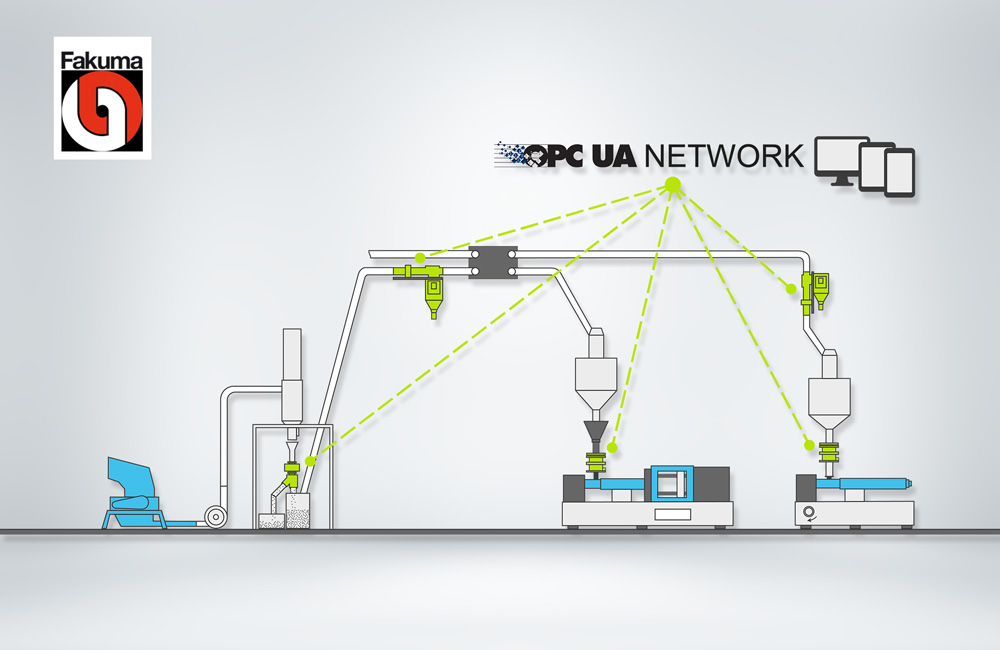

The brochure begins with chapters that specifically address the requirements of both plastics manufacturers and plastics processing companies along their production lines. Sesotec already provides a vision for the future of the industry here: the introduction highlights the interaction of high-tech sensor technology for data acquisition and processing, its evaluation and visualization via software applications for maximum planning reliability and control over the production processes. The main section is dedicated to detection hardware, but instead of simply listing the features of each device category, a practical overview of specific customer applications is provided so that the devices relevant to the customer are immediately recognizable. The overview is rounded off with the comprehensive service portfolio, which is available to all Sesotec customers worldwide. It not only ensures the commissioning and functionality of the systems, but also extends their service life.

The brochure highlights the entire Sesotec product portfolio, which is specially tailored to the needs of the plastics industry. Among other things, it presents

- Metal detectors reliably protect against machine damage, production downtime, complaints and recalls by detecting all metallic foreign bodies, whether made of iron, steel, stainless steel or non-ferrous metals such as aluminum, copper and brass.

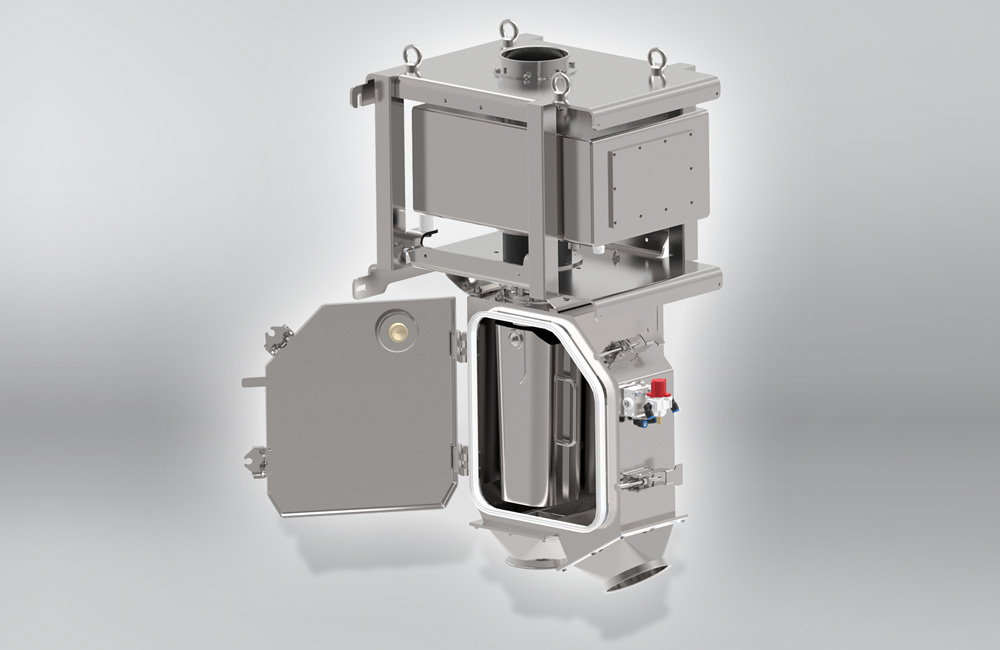

- Metal separators detect and remove metallic contaminants using an integrated separating unit, protect against machine damage and minimize material loss during separation.

- Magnetic systems for free-fall applications provide reliable protection in production lines for powdery and granular bulk materials and can be integrated quickly.

- Material management systems for returning recyclates and regrind to the cycle increase the predictability and efficiency of production through quality assurance in input and output control.

- Sensor and software solutions offer transparency, production optimization and control with the browser-based Sesotec Insight.WEB visualization software to ensure profitable and sustainable production.

- Last but not least - the “Fast Lane” products PROTECTOR, RAPID VARIO-FS and GF can be produced ready for dispatch in just five working days from receipt of order.

“The overview of our portfolio is a valuable resource for companies looking to optimize the efficiency, safety and quality of their plastics production processes,” explains Dietmar Dieing, Vice President Sales PI Plast. “With the brochure, we offer a clear guide and show how the various systems contribute to increasing profitability in production and processing.”

The brochure is now available here: → Download