The development of our metal detection systems was focused on one thing in particular: Your priorities. In-depth analysis and background discussions have revealed the key requirements for foreign object detection. On this basis, we have intensively researched solutions. This has resulted in our Sesotec 6-priorities concept with practical answers to your challenges.

The automatic venting of the pneumatics in the event of an emergency stop and compressed air monitoring, as well as the ejection control, ensure all-round safe operation for people and products.

Thanks to a large touchscreen, intuitive user guidance with quick access to the most important system functions, a help function and features such as the Auto-Learn function, our tunnel metal detectors offer particularly easy everyday handling.

Robust and hygienic housings allow easy cleaning.

Intelligent sensitivity adjustment and high interference immunity prevent false positives and increase profitability.

With warranty services, combined on-site and remote service, and targeted training, you have optimal support for smooth operation.

Our tunnel metal detectors guarantee reliable detection of magnetic and non-magnetic metal contaminants with single, dual, multi or multi-simultaneous frequency technology.

Our compliance software package for seamless and efficient documentation consists of

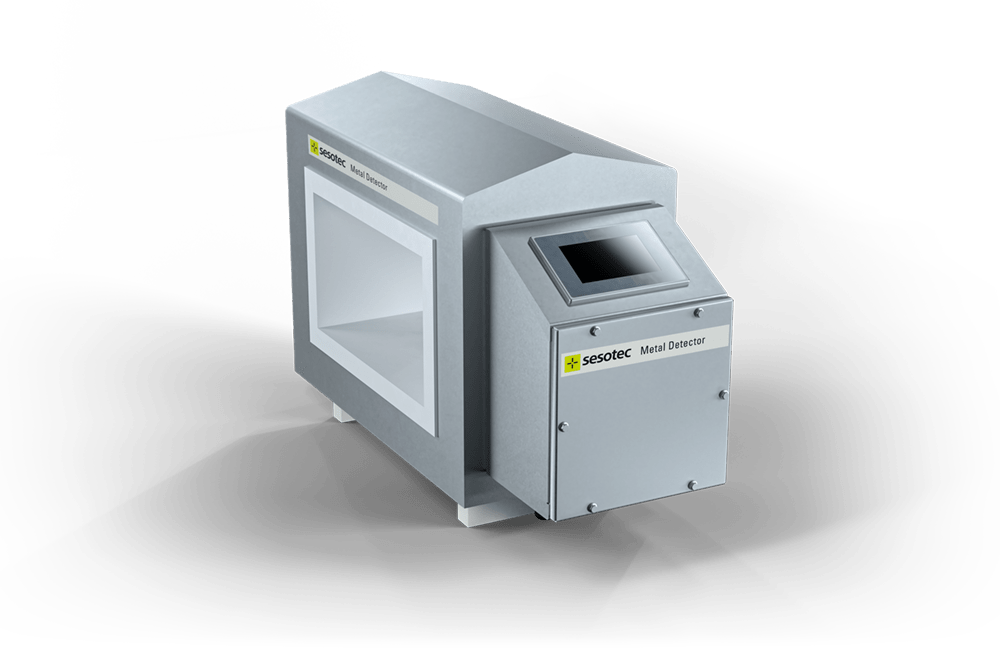

The entry-level model for inspecting lumpy and bulk materials on a conveyor belt with good detection accuracy

The standard model for the examination of piece and bulk materials on a conveyor belt with a very good detection accuracy

The high-end model for best detection accuracy even for products with high product effect

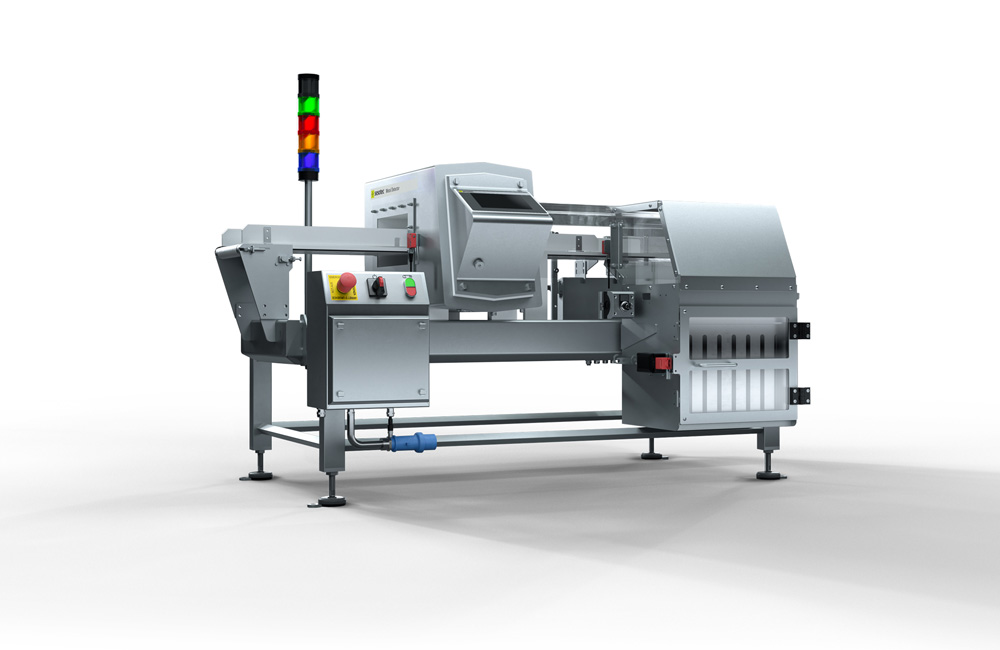

VARICON+ is a complete system with integrated conveyor belt. It is available with GLS, GLS MF and INTUITY metal detectors for best detection accuracy and can be used in both dry and wet areas. The extremely short metal-free zone of the Sesotec metal detectors enables the shortest conveyor belt lengths. The construction of robust stainless steel guarantees maximum stability.

With the UNICON+ conveyor belt series, we realize individual adaptations and solutions for optimal installation in the customer‘s own environment. UNICON+ is based on the proven and robust VARICON+ conveyor belt technology and can be designed for dry or wet cleaning.

Interested? Get an even more detailed insight in our brochure now!

Download

Let our experienced sales engineers advise you without obligation or request more detailed information on our products.