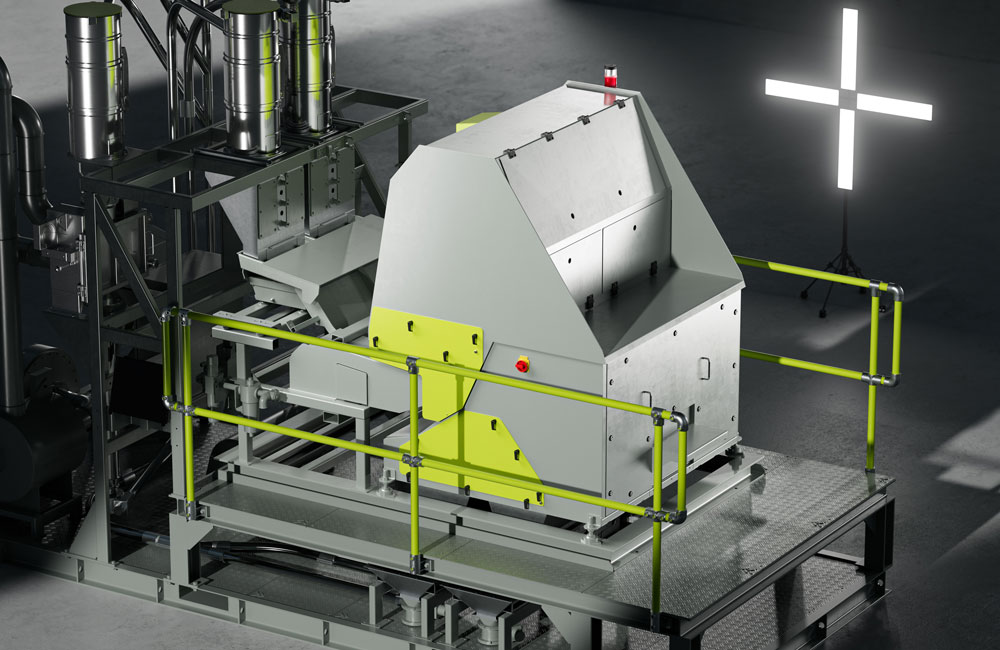

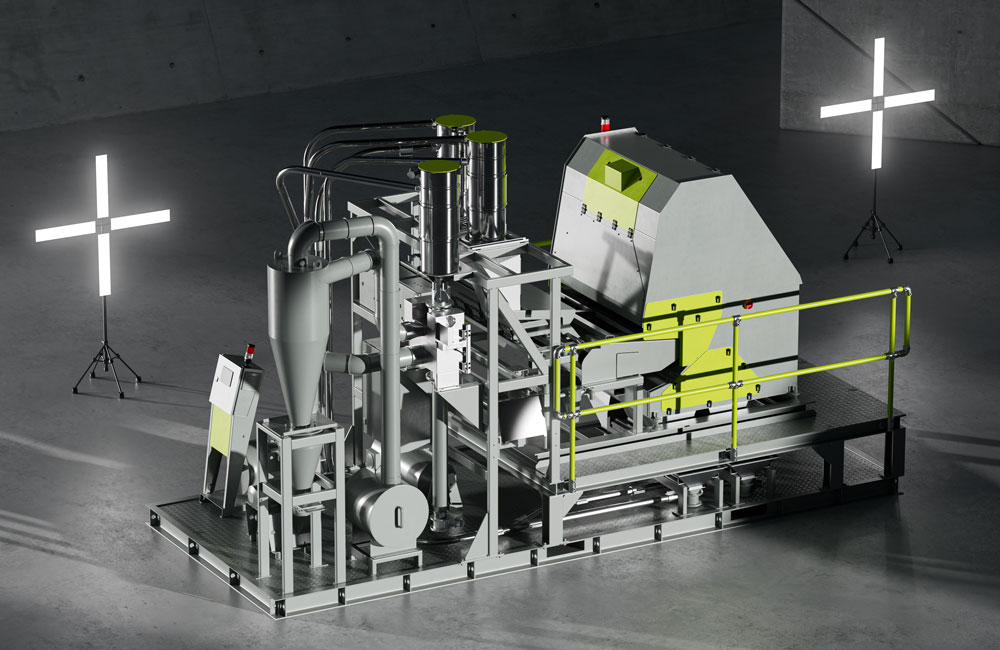

In order to be able to sustainably produce and reliably process with foreign material, product purity in the process is the first step. With our mobile multi-sensor sorting platform PRE-SORT, plastics processors have the quality of their regrind in their own hands. The compact complete system efficiently and reliably detects and separates plastic types, colors, and metals from regrinds of various qualities – fully automated and according to the requirements of the production line.

The plastics processing industry has to face constantly growing demands:

With our innovative concept for material presorting, we help you to produce independently, profitably and highly efficiently. Your advantages:

With our PRE-SORT you have full control over the quality of your input material and make yourself less dependent on external suppliers. Thanks to sensors that can be combined in any way and the possibility of selecting different sorting sequences depending on the material composition, the mobile sorting platform offers full process flexibility. Following the idea of a plug-and-play methodology, the system is ready for immediate use and fits seamlessly into any production environment thanks to its compact design.

Mobility

Due to its design in the form of a self-contained sorting platform, the PRE-SORT can be transported from one location to another and can thus be used flexibly and at different locations.

Process variability

The PRE-SORT offers maximum process flexibility through any combination of sensors and a choice of different sorting sequences. Thanks to two tracks for automated double sorting, the sorting platform also ensures first-class material quality.

Sensor flexibility

Intelligent sensors for color, polymer and metal sorting are combined in this device. Depending on the sensor combination selected, sorting can thus be performed according to colors, types of plastic and metals, or only according to individual factors.

Due to its design in the form of a self-contained sorting platform, the PRE-SORT is an efficient complete solution for the sorting of regrind and can be transported from one location to another – thus it is flexible and

can be used at different locations.

The VARISORT COMPACT multi-sensor sorting system is not only characterized by its extremely compact design. High-resolution sensors, which can be combined in any way, and state-of-the-art signal evaluation technologies guarantee high detection accuracy and an evaluation of up to 500,000 parts per second.

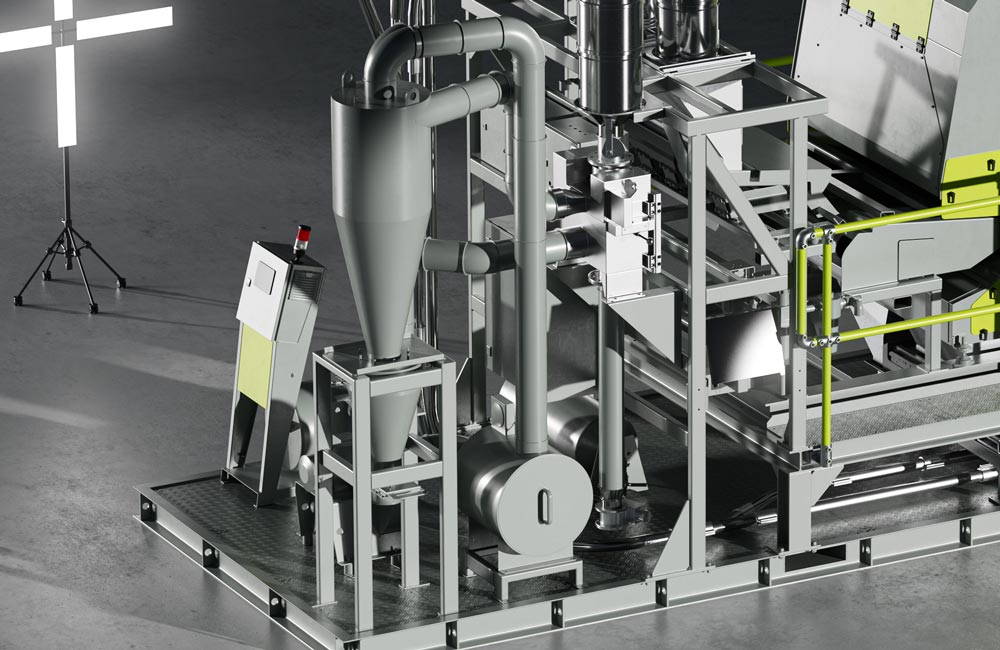

A counterflow classifier system reliably separates dust and fine particles from the ground material.

Standard vacuum conveying units with a central vacuum station ensure smooth material transport via the dedusting system to the VARISORT COMPACT. Extraction can be from bins, silos, big bags or even octabins.

The conveyor technology and sorting are centrally connected via a control unit. The integrated automatic start and stop function ensures the highest possible operating convenience.

Interested? Arrange a consultation appointment with one of our experts now

PRE-SORT: Maximum flexibility

The modular design of the sorting system allows the combination of up to three sensors (CMN). Sensors can be updated at any time without any problems.

High-resolution color line scan camera for approximately 17 million teachable colors combined with innovative lighting options

Inductive metal sensors for identification/ detection of magnetic and nonmagnetic metals

Hyperspectral camera for identification of different polymer types and materials as well as for various special applications

Interested? Get all information about the PRE-SORT compact in our brochure now!

Request more information or a personal consultation now without any obligation:

Let our experienced sales engineers advise you without obligation or request more detailed information about our product.