Metal detectors for food primarily are used for the purpose of consumer protection. Despite maximum care metallic contaminations of food products during the production process cannot be fully excluded. Metal particles that enter the product during the production process or already are contained in the raw material may cause serious injuries of consumers. The consequences for the producing company are numerous and serious and include compensation claims and expensive recalls. Even bigger and longer-lasting damage is caused by the negative brand image and the loss of consumer trust caused by impure food products.

Metal detectors for food provide effective protection against ferrous

and non-ferrous metals (aluminium, stainless steel, etc.). They can be

installed in every step of the production process and can be used for

many different applications, e.g. for the inspection of bread and bakery

products, meat and sausage product, fruit, vegetables, dairy products,

spices, sugar, etc.

In addition to consumer protection, metal detectors also are used to

protect machinery. Even smallest metal particles can lead to machinery

failure. Expensive repairs and production downtimes are the

consequences, often followed by revenue decreases.

When used for machinery protection, the metal detector is installed

directly before the machine to be protected. If, as in most cases in the

food industry, consumer protection is the goal, several inspection

points are useful. An inspection of raw material has the advantage that

metal particles are separated before they are broken up into smaller

pieces which might be harder to detect. Inspections at critical control

points (HACCPs) during the production process are recommended to notice

machinery failures (such as broken blades) in time.

Consequently, food products in their final stage after packaging are

inspected once again with a metal detector (or an X-ray system) to fully

exclude contamination.

For optimal product protection an inspection of raw materials, of several critical control points, and a final inspection of the finished product are recommended.

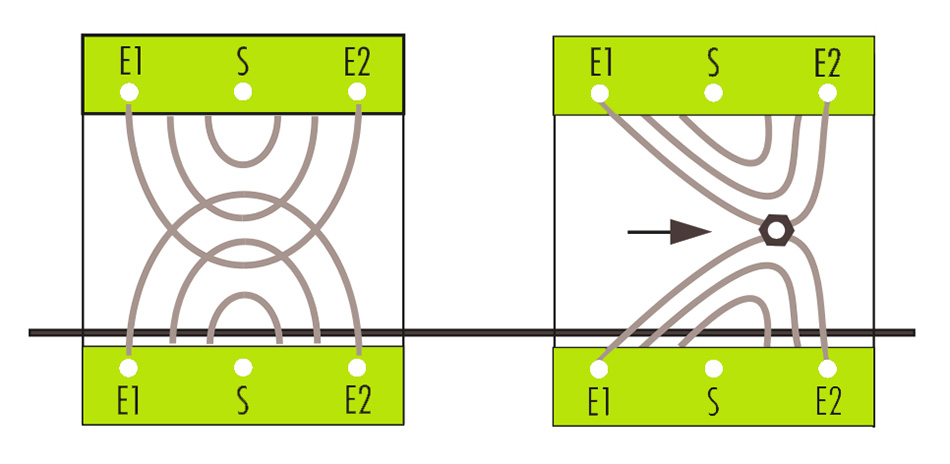

Such metal detectors are equipped with a transmitter coil and two receiver coils. The transmitter coil generates a constant electromagnetic field. When a metal particle passes the detector it interferes with the electromagnetic field, causing a signal to be detected by the receiver coils. The electronic unit in the metal detector analyses this signal, evaluates it and signals a metal contamination. As a rule metal detectors in the food industry are equipped with automatic reject units that directly separate the contaminated product from the production line.

The selection of your country allows us to offer the optimal content for you.

We have detected the following country based on your IP address:

If this is not correct, please choose your country below.

Albania Andorra Armenia Austria Aserbaidschan Belarus Belgium Bosnia-Herzegovina Bulgaria Croatia Cyprus Czech Republic Denmark Estonia Finland France Georgia Germany Greece Vatican City Hungary Iceland Ireland Italy Kazakhstan Kyrgyzstan Lattvia Liechtenstein Lithuania Luxembourg Macedonia Malta Moldavia Monaco Montenegro Netherlands Norway Poland Portugal Romania Russia San Marino Serbia Slovakia Slovenia Spain Sweden Switzerland Tajikistan Turkey Turkmenistan Ukraina United Kingdom Uzbekistan

Anguilla Antigua & Barbuda Aruba Bahamas Barbados Belize Canada Cayman Islands Costa Rica Cuba Dominica Dominican Republic El Salvador Greenland Grenada Guadeloupe Guatemala Haiti Honduras Jamaica Martinique Mexico Nicaragua Panamá Puerto Rico Saint Kitts and Nevis Saint Lucia Saint Vincent and the Grenadines Trinidad and Tobago Turks and Caicos Islands USA United States Virgin Islands British Virgin Islands Netherlands Antilles

Algeria Angola Benin Botswana Burkina Faso Burundi Cameroon Cape Verde Central African Republic Chad Comoros Republic of the Congo Democratic Republic of the Congo Ivory Coast Djibouti Egypt Equatorial Guinea Eritrea Ethiopia Gabon Gambia Ghana Guinea Guinea-Bissau Kenya Lesotho Liberia Libya Madagascar Malawi Mali Morocco Mauritania Mauritius Mozambique Namibia Niger Nigeria Rwanda Sao Tome and Principe Senegal Seychelles Sierra Leone Somalia South Africa Sudan Swaziland Tanzania Togo Tunesia Uganda Zambia Zimbabwe