Circular Economy

08/12/2020 |

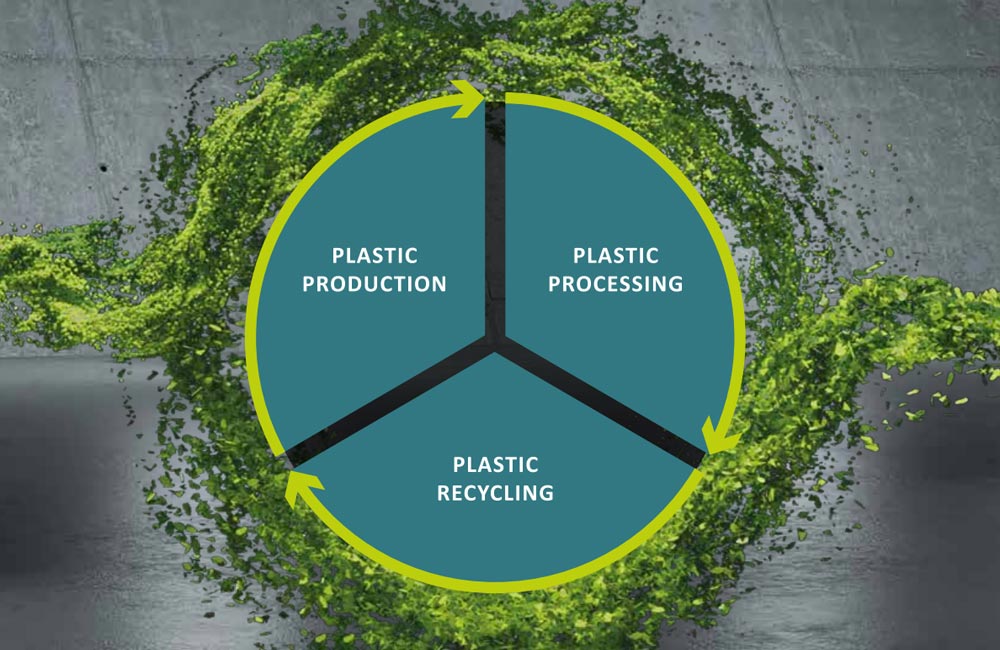

The plastics cycle and contaminated recyclate

Recyclate from used plastic is a valuable material that is used in manufacturing new products. Manufacturers and fabricators process it in flake, powder or granulate form, but only if the recyclate is of good quality. Different plastic types, incorrect colours or foreign objects can have a significant impact on recyclate quality. A distinction can be drawn between three main types of recyclate contamination: foreign plastics, discolouration and foreign objects.

These contaminants can enter the processing cycle at almost any time. Even the plastic waste from collection systems, which is pressed into balls, contains an array of materials that don’t belong there. Recycling companies are required to carefully sort their plastic waste to safeguard the quality of their recyclates. Random samples suggest that contaminants could account for up to 80% of plastic waste.

Undetected, they can leave a real mark on the recycled products, meaning complaints from consumers and more hassle for the manufacturer. If the contaminants are made of metal, they can even damage production machinery and cost plastics processors a significant amount of moneyDetecting materials and plastics with near-infrared sensors

Separating different types of plastic is one of the most challenging tasks in the recycling process, as collected plastic waste is often made up of a mixture of different materials. Plastic bottles made from polyethylene terephthalate (PET) are one example of a material that can usually be recycled easily. Plastic bottle caps, on the other hand, are often made from a different material such as polyethylene (PE) or polypropylene (PP), which have different properties to PET and cannot be recycled in the same way. Labels on plastic bottles can also be made from a different type of plastic. It’s the same story with meat or cheese packaging, where the tray and the sealing film are often also made from different materials.

Generally speaking, there are no systems in place to collect different types of plastic; implementing such a system would be expecting too much of consumers, anyway. For this reason, recyclate manufacturers rely on high-performance sorters. These machines use near-infrared sensor technology to sort plastics into similar fractions and recognise contaminants such as stones.Camera sensors detect colours

These sorting systems are also equipped with

colour-detection sensors. After all, not only should recyclate flakes or grains

have uniform characteristics, they should be uniform in appearance as well.

However, manufacturing recyclate in consistent colours is a challenge. The

colourful print on a plastic bottle can lead to unsightly defects in a recycled

product. And who wants an electrical appliance with grey streaks across the

white housing because the recyclate had discolourations? Systems equipped with

camera sensors are able to identify discoloured particles and eliminate them.

For example, infrared sensors combined with colour detection can tell whether

PET bottles are made from colourless or coloured material.

Sorting out metal parts using magnets and inductive sensors

Foreign objects are the third type of contaminant. Small metal items, such as paperclips, nails or other tiny objects, are often the most frequent cause of contaminated recyclate. They can cause some considerable damage, in spite of their size. The metal objects can enter the processing cycle at almost any time through plastic waste, due to mistakes in sorting, for instance. Inductive metal detectors and magnet systems are the solution as they can recognise these foreign objects and remove them from the system.

Crushing methods can also be responsible for foreign objects in recyclate. Here, machines shred plastic waste before later sorting the individual parts. However, the blades on the shredding machines wear down over time, introducing metal particles into the recyclate and therefore into the manufacturing process. When recyclate is produced, these particles are melted into the plastic and encased by it. If the contaminated recyclate is processed, the invisible pieces of metal can damage manufacturing machinery and lead to extended periods of downtime. That’s why they must be properly removed from the recycling system. Equipping conveyor pipes and processing machines with magnets and/or inductive metal detectors and separators is the best way to do it.Overseeing the whole process

Closely coordinated sorting, manufacturing and processing systems produce outstanding results. Pre-sorted plastic waste, which is usually pressed into balls, is checked for contaminants after it is dissolved. It is then ground and the flakes meticulously washed. The flakes then go through a second sorting process. Having both sorting systems from the same manufacturer often boosts overall performance, not to mention lowering service costs.

Ultimately, it all comes down to manufacturing a recyclate that can be used for its intended purpose. Particularly high-quality material can be used to manufacture new food packaging. Anything that doesn’t meet “food-grade” standards is suitable for manufacturing synthetic fibre, packaging or insulation.Product design impacts recyclability

Sorting machines could be even more efficient if

the composition of plastic products were to make recycling easier, something

that has so far not been seen enough. Developers prefer to optimise their

materials and products for the intended purpose, as this opens up more

opportunities on the market. One example is black plastic bottles, whose modern

appearance makes them popular among particular target groups. However, due to

its light-absorbing properties, the material used to make these bottles cannot

be sorted easily, which is why black plastic often ends up being incinerated.

There are a number of rules for manufacturers to follow to design products to be recycling-friendly. For example, it is better to use a single type of plastic rather than composite material. If multiple layers are used in a product, they should be easy to separate. It also makes sense to tell consumers to separate packaging components, for instance by removing labels before throwing products away. Of course, the ideal solution is for labels to be made from the same material as the packaging.

So far only a handful of eco-conscious manufacturers have really got to grips with sustainable product design. And legislation moves at a snail’s pace. “Regulations governing recycling-friendly product design are the exception, not the rule,” says Michael Perl, Group Director Sorting Recycling at Sesotec. “Manufacturers need to be incentivised to use recyclate as a pure secondary material in plastics production.”

However, Bartosch Jauernik, Plastics Product Manager at Sesotec, admits that shelf life and useful properties are important factors in selling a product: “Recyclability should be held in the same regard and integrated into the product development process from square one. In addition, the use of recyclate as proposed by the Resources Commission at the German Environment Agency could be enshrined in law through what is known as the substitution quota.” The substitution quota defines what volume of primary resources should be substituted with secondary resources or recyclates. Not only would the substitution quota provide a new benchmark of recycling success, it would also impose a minimum requirement for recyclate use in products.

But the entire chain – from legislator to manufacturer to retailer to consumer – needs to pull in the same direction to embrace sustainability, regardless of temporary factors such as pricing trends.