Quality assurance and specifically contaminant detection are key concerns at meat-processing plants. Contaminants can damage machinery or even pose a risk to consumer health and may trigger recalls. We have the right machines and the necessary experience to minimise these risks.

For decades, Sesotec has specialised in systems for industrial

contaminant detection. We provide a complete range of leading technology that includes

metal detectors and X-ray systems for the reliable detection and removal of

contaminants. Our machines and systems of course comply with the special

hygienic requirements of the food industry and meet the prescribed standards

for audits.

Contaminated raw materials, machine wear and objects belonging to machine operators are possible sources of contaminants. Examples include:

Looking for more information or advice? Contact us

Unser White Paper beschreibt einige der Herausforderungen, die sich

in der Fleischindustrie hinsichtlich der Produktreinheit und -sicherheit

ergeben und erklärt die verfügbaren Technologien, die für die Detektion

von Fremdkörpern zur Verfügung stehen.

Our White Paper informs you about the criteria that

need to be considered when you choose machines and systems for the

protection against contaminants and for metal detection.

Our White Paper describes the development of technologies in

contaminant detection in the food industry.

In this White Paper we show you the key benefits and

diverse application possibilities of x-ray technology and how these systems help

you to ensure your product quality.

With our booklet

about X-ray inspection of food products we give you an overview of x-ray

inspection in general, important food standards and Sesotec's

solutions.

In our e-book we show you, amongst others, what challenges the development of the world's population and especially food safety pose for manufacturers and processors and how they can still be mastered.

This

Whitepaper outlines the legal requirements for food safety in some

of the world’s major markets and compares them with the most common standards.

This information is meant to help food industry companies choose the best

standard for their business.

Despite the breadth of technology available for foreign object detection, certain types of food products remain difficult to inspect via conventional methods. The reason for this is that some foods have high levels of product effect, which can interfere with metal detection. This white paper examines the phenomenon of product effect, the problems it can cause, and why artificial intelligence offers an innovative and promising solution.

This guide is intended to help quality managers and production managers in food processing companies to generate a common understanding regarding validation and verification processes in their own organization and to implement appropriate procedures.

Download

As the world population grows and global living standards rise, the food industry is confronted with a number of challenges and opportunities, especially in the area of Food Safety. This e-book is meant to offer a comprehensive overview of the varying and influential factors shaping the future of food manufacturing and processing.

In the first part of our e-book article series "Food Safety", we looked at the factors that play an important role in the food industry from different perspectives. In the second part of the article series, we will discuss what support is available for the effective implementation of various food safety measures.

We explain the path from preventive to predictive maintenance and how this will make your production more efficient in the white paper "Future-proof: The path from preventive to predictive maintenance in the food industry”.

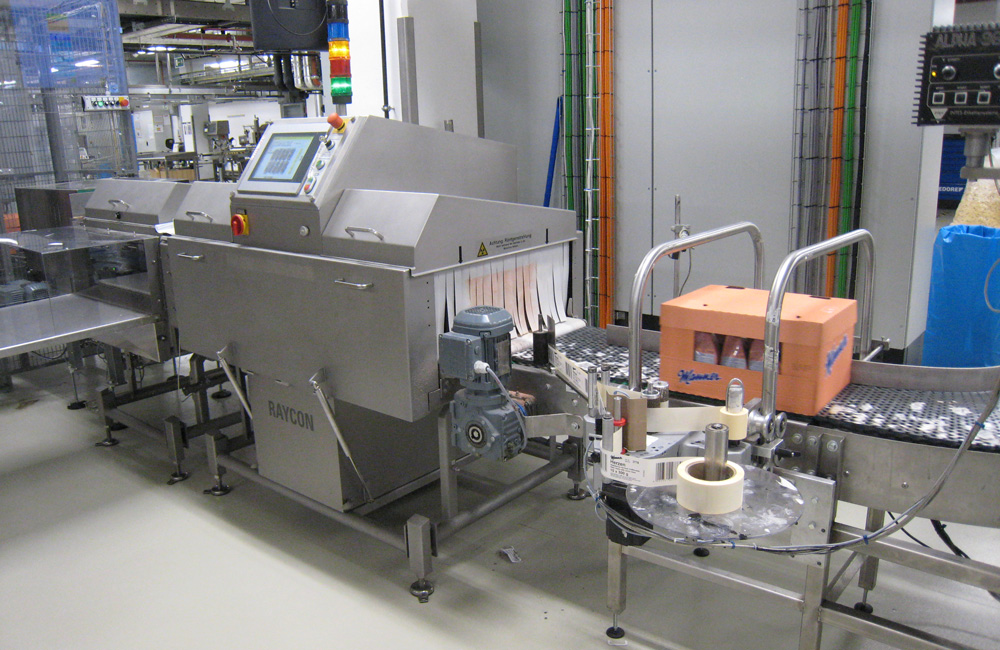

Founded in 1890, the Josef Manner & Comp. AG is the number one specialist for wafers, dragées,

and marshmallow products

in Austria.

As a leading

manufacturer of product

inspection technology, Sesotec supplied Manner with three RAYCON x-ray systems to help them renew their IFS certification in 2019. The solution was a success:

their IFS certificate was renewed and both production

sites continue to operate at the highest level of accreditation.

Founded in the 1960s, H. Loidl Sausage Producers and Distributors GmbH & Co KG attributes their rapid growth to the high quality of their salami products. Once ripe, some Loidl salami products are packaged in slices. This requires

removing the casing and the aluminum clips by hand. In some cases, residue from the aluminum clips remains on the salami. The standard metal detection solutions Loidl had used up un til that point were not sensitive enough to reliably detect the metal contaminants. So Loidl turned to Sesotec in search of a solution for detecting and automatically rejecting metal contaminants from salami sticks.

Among the favorite products of Tunacor Fishing Ltd are their fish sausages, which are especially celebrated in Spain. However, every now and then they would receive complaints from customers about bits of metal in the sausages.

FF Frischfleisch AG was searching for a way to fully trace 100% of products subject to complaints. Such a solution would require the systematic documentation of production.

In cooperation with Kundert, the Swiss sales partner, Sesotec was able to develop a solution to this challenge onsite.

Many customers face the problem of lacking the knowledge of which setting parameters can cause a significant change in product safety and process relevance. A validation process can aid these customers to overcome this challenge and take a successful path towards compliance with food safety standards. Such as process can also be used as a service.

Milchwerke

Schwaben processes 410 million kilograms of milk and whey each year.

Metal

detection must be installed at various checkpoints to control for the quality

of dairy products. Butter and rice pudding, for example, are transported

through pipelines prior to filling. In

order to ensure these packaged products are free of metallic contaminants,

metal detectors are used.

As a new major company with the highest quality requirements, CREMER needs a powerful and reliable metal detection system to ensure that its production facilities meet international standards and reliably produce safe products. All in the interest of food safety.

EUROVERDE‘s entire product range is the result of a quality process at the highest level. In the field of foreign matter management, EUROVERDE has been using various metal detectors for years to separate metal particles of any kind from the products.

Brochure about the production and processing of meat products.

Kompaktes Metall-Detektionssystem mit Förderband zur Untersuchung von Stückgütern

Product inspection system for slim and packaged products at moderate pricing

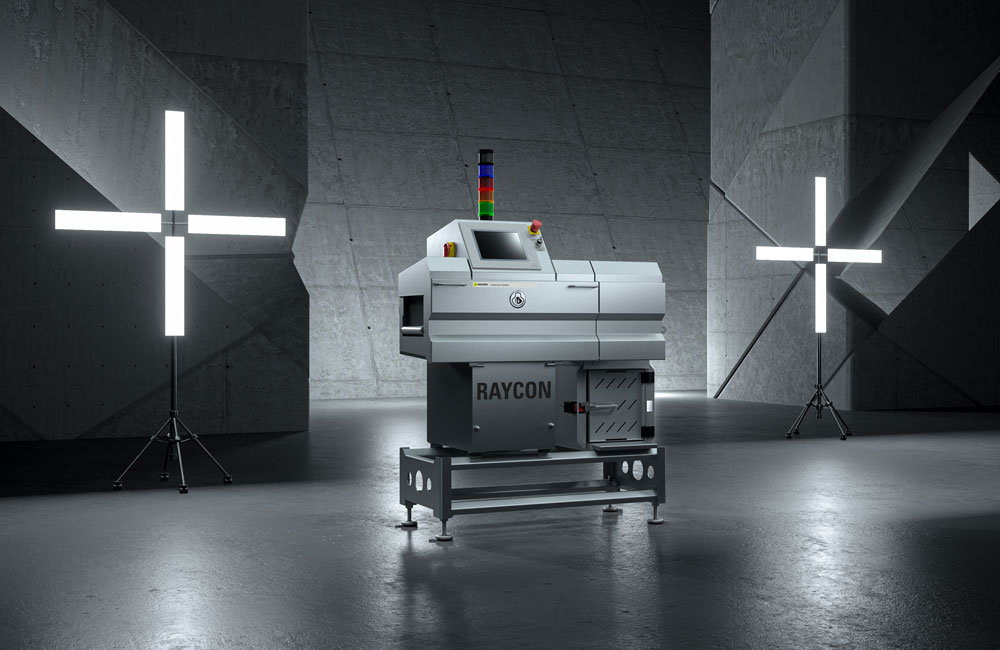

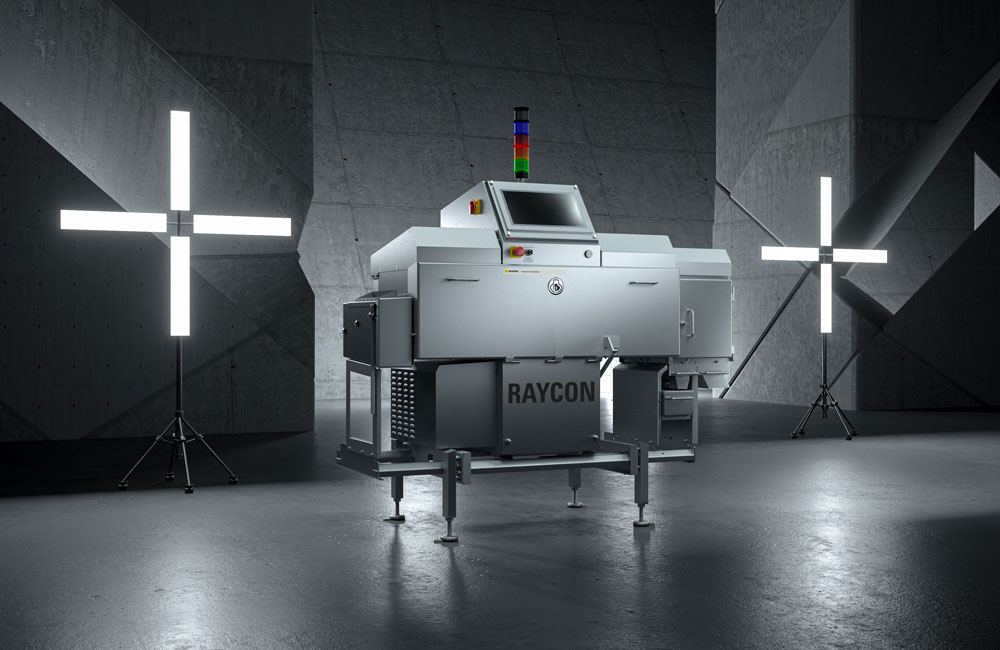

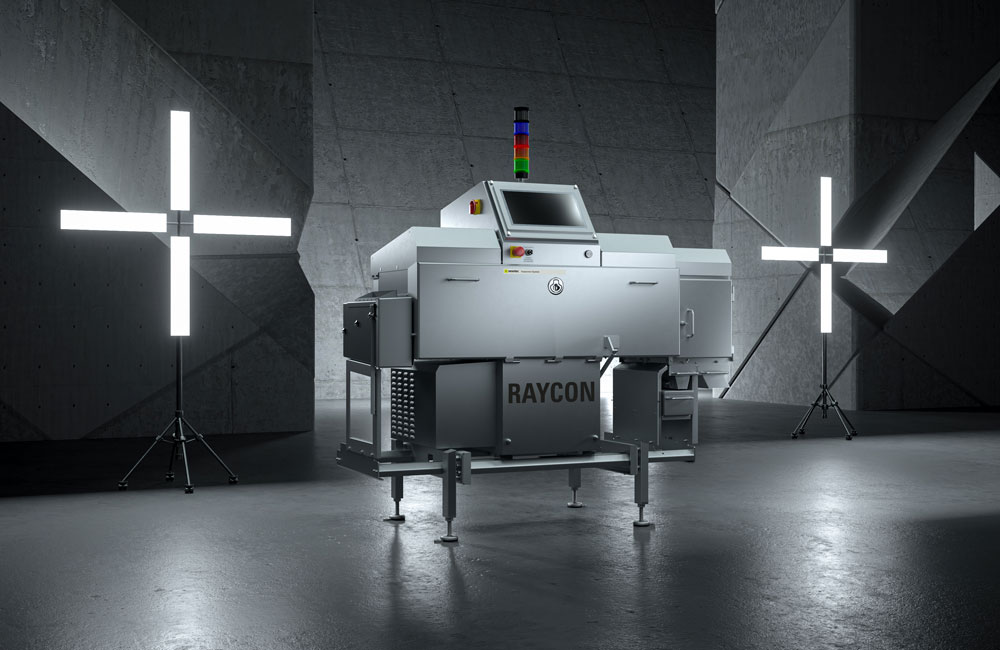

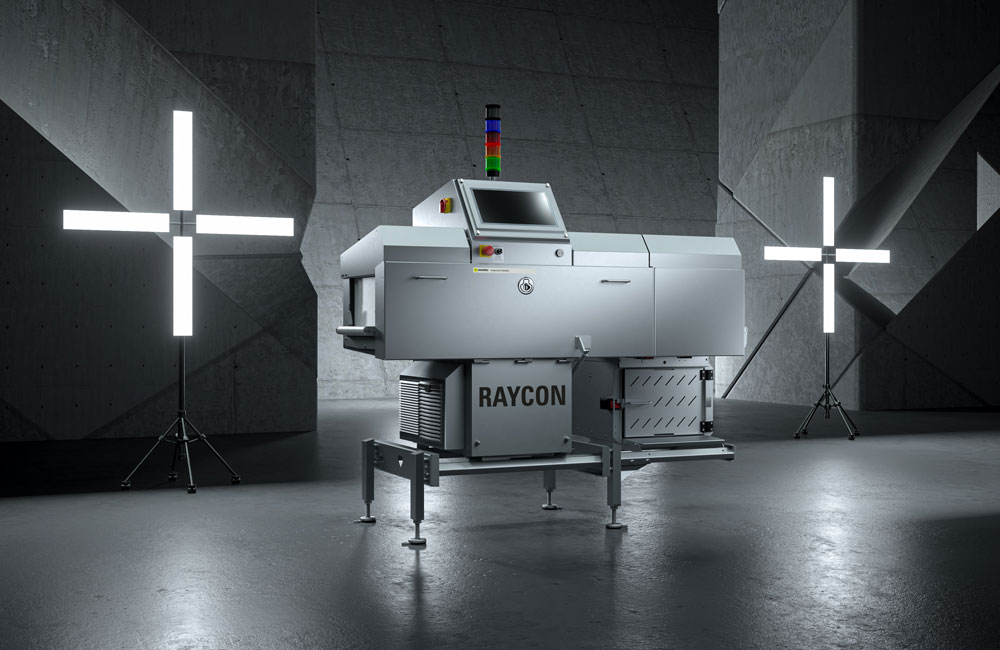

The RAYCON D+ MX LW is the standard model for inspecting lightly

packaged products. Therefore, this unit is equipped with an innovative

conveyor belt design that does not require curtains.

RAYCON D+ HX LW is the high-end model for inspecting light packaged

products. Therefore, this device is equipped with an innovative conveyor

belt design that does not require curtains. It achieves the highest

detection accuracies.

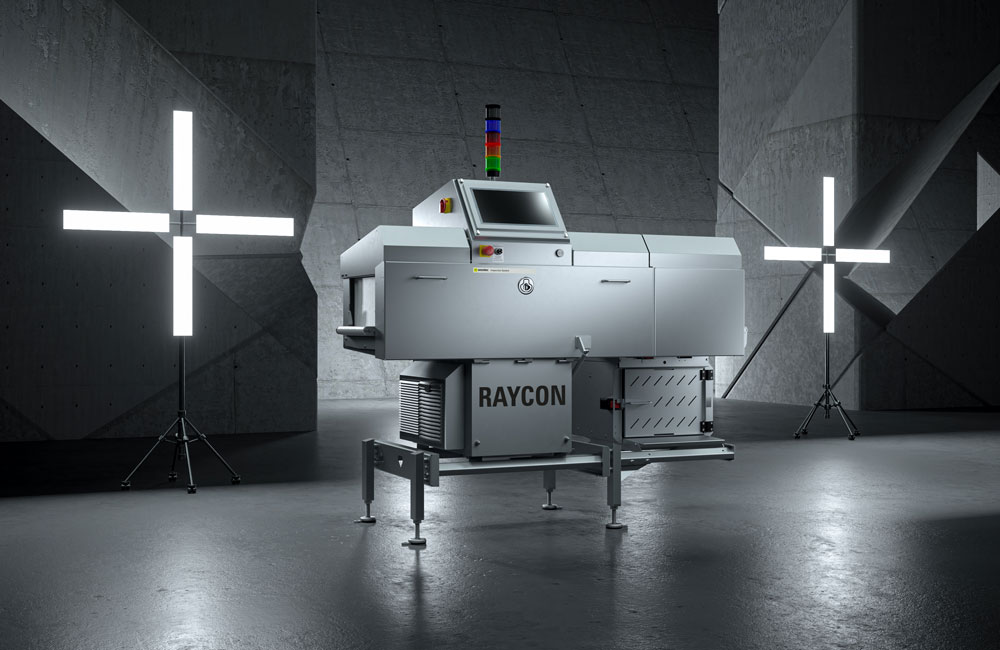

The RAYCON D+ MX BULK is the standard device for inspecting unpacked

bulk materials. Pneumatically driven flaps ensure minimal loss of good

material.

RAYCON D+ HX BULK is the high-end model for the inspection of unpacked

bulk materials. It achieves the highest detection accuracies.

Pneumatically driven flaps ensure minimal loss of good material.

The RAYCON D+ HX Dual Energy high-end X-ray inspection system detects

difficult-to-detect low-density contaminants such as certain plastics

and cartilage.

Sesotec

has completed the proven RAYCON product family and thus offers X-ray inspection

solutions for all applications in the food industry.

Our free-fall metal separators have been specially developed for use in free-fall conveying lines with hygienic requirements. They reliably detect and separate magnetic and non-magnetic metal contaminants from granular, fibrous and powdered bulk materials – even if they are enclosed in the product.