Circular Economy

25/07/2019 |

Plastic: part of the problem… part of the solution - Part 3: Sorting technology

Each year, Europeans generate 25 million tonnes of plastic waste. At a global level, 78 million tonnes of plastic waste is created annually. The world has to respond to this global problem together, as recycling rates everywhere have been at a low level so far: 30% in Europe, 25% in China, and just 9% in the USA (Plastikmüll-Statistik 2017). A large portion of the supposed waste is still incinerated, or ends up in landfills and the environment, which harbours risks for our water, air, and food chain.

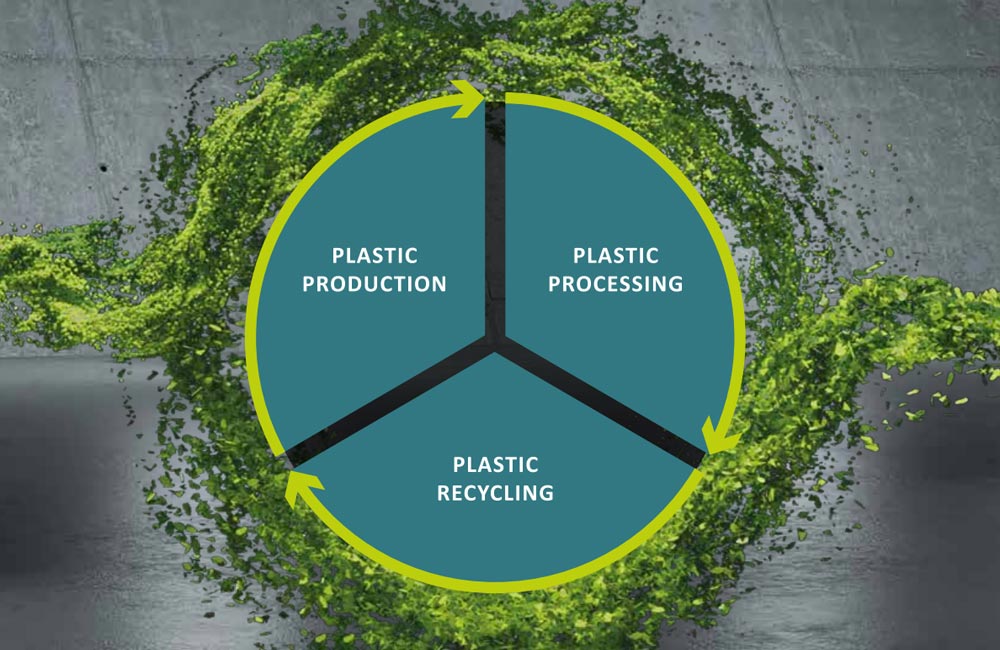

To achieve a circular economy, it’s important

that all players contribute to this task: from product design and manufacture on the part of the plastics

industry, along with conscious use and avoidance of plastics as well as waste

separation on the part of consumers, followed by proper recycling and sorting

by the waste and recycling sector, all the way up to conversion into

high-quality secondary raw materials and their use in the manufacture of new

products.

How does a circular economy work?

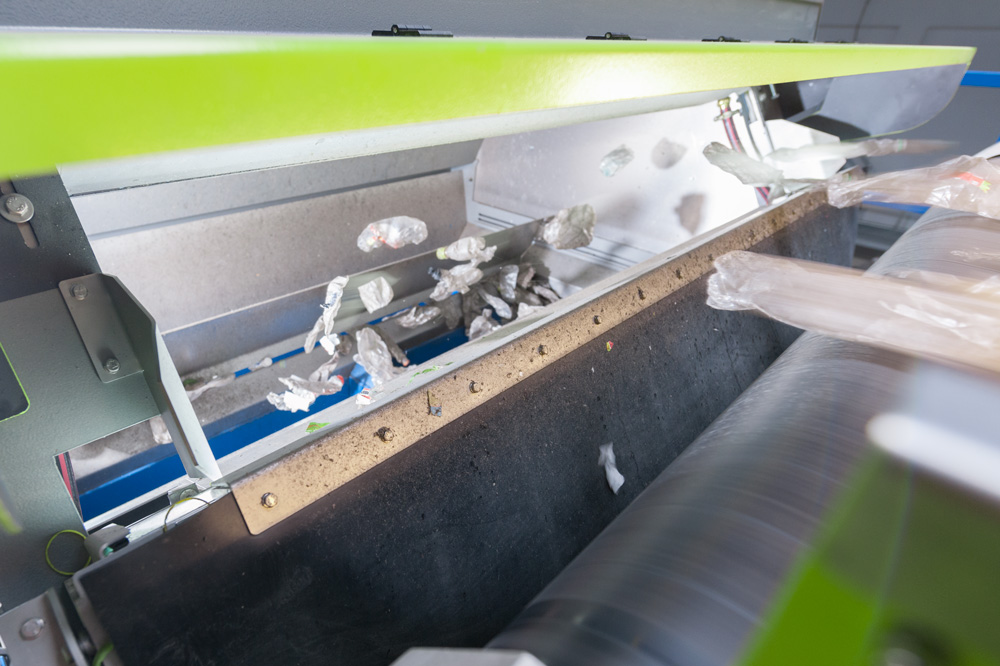

And this is exactly where Sesotec’s expertise is

called for. Technology that can sort waste with great precision and thereby

supply pure source materials has been around for a long time.

Sesotec’s

sorting systems sort the collected plastics (bottles, flakes, and ground

material) based on a range of criteria, such as colour, shape or type of

material. They are equipped with

sensors that can be combined to suit the particular application scenario.

Infrared technology enables the systems to recognise different materials.

Camera systems allow the material flows to be sorted by colour and shape.

Special metal sensors can also be built into the systems.

Sesotec

has taken on the industry’s challenge, and more than 600 of its sorting systems

for plastics recycling are in use worldwide. In

many application scenarios, purity levels of more than 99.9% have been

achieved. Only high-quality sorted materials can facilitate high-quality

material recycling. The

challenges that arise in sorting are caused primarily by material composites,

plastics with additives, labels, and dirty plastics.

PET as a model

Polyethylene terephthalate – better known as PET – is a highly reusable material as it does not lose its properties when recycled, making it 100% recyclable.

German consumers return 99% of the PET bottles that require a mandatory deposit. 93.5% of these bottles are sorted and recycled, either into new PET bottles (34%), films (27%), textile fibres (23%) or strapping and cleaning product bottles (16%).

Read the other parts of this series here:

Part 1: A global problem

Part 2: The European Union’s solution

Part 4: Efficient use of recyclates