Plastics

07/05/2019 |

Advantages and benefits of OPC UA in the plastics industry

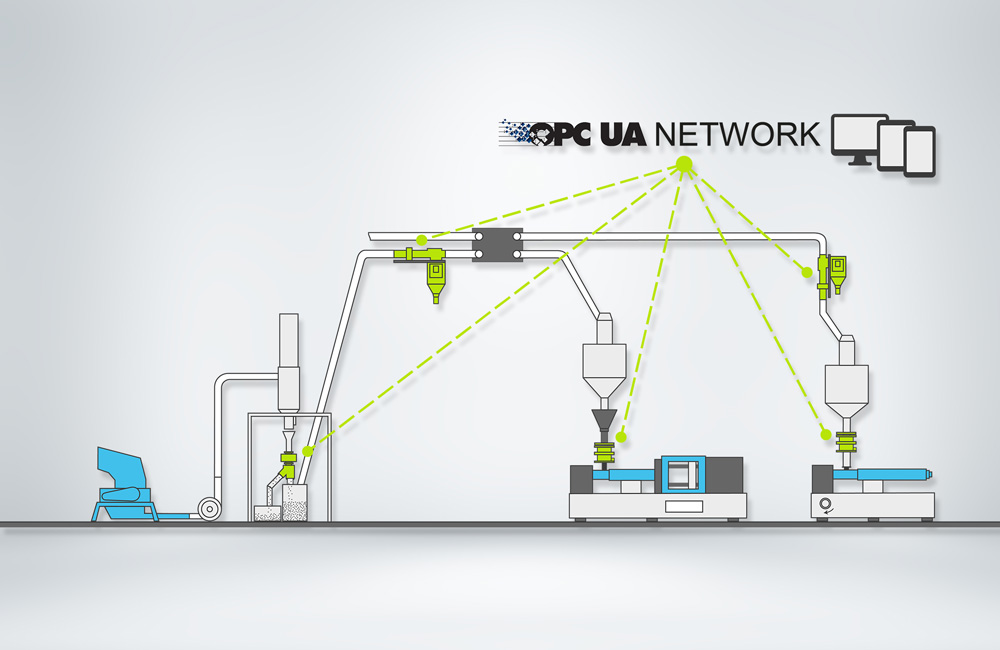

For years now, the world has been talking about “Industry 4.0”. The exchange of data in production plays an important role in making the introduction of Industry 4.0 a success. The open communication protocol OPC Unified Architecture, or OPC UA, is increasingly gaining popularity as a way of promoting data sharing. But what advantages and benefits does using OPC UA offer the plastics industry, for example?

In the plastics industry, the OPC UA machine communication standard helps to optimise processes from production to service while minimising the loss of time, resources and products (rejects), thereby ensuring top quality and maximum value creation.

An example of OPC UA communication: metal separator “talks” to mixing and dosing unit

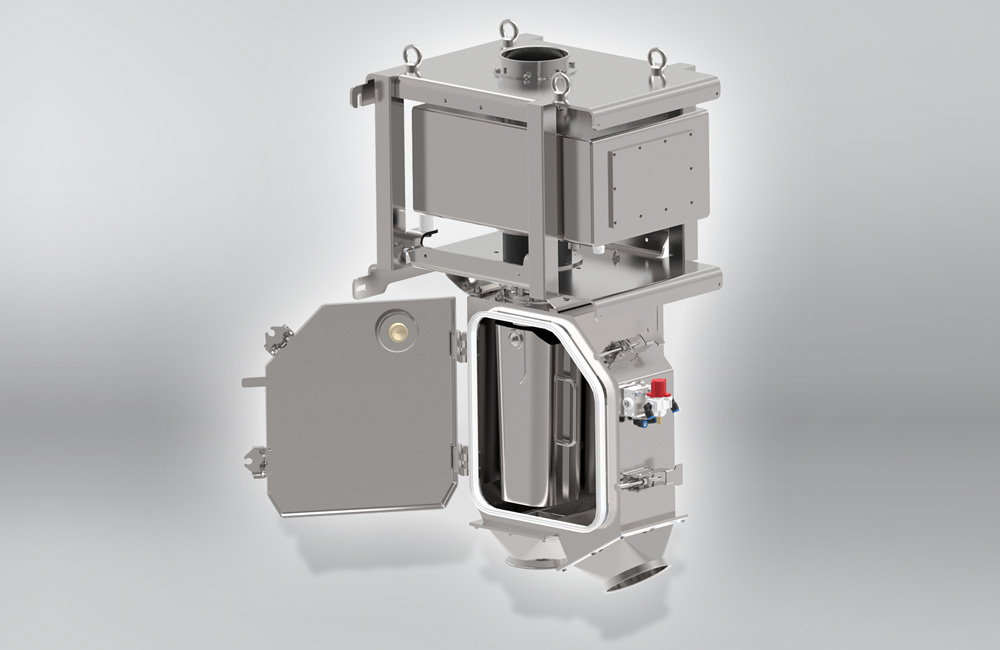

A plastics company that produces caps and lids for the cosmetics industry, for example, may have multiple injection moulding machines in use on the shop floor. To increase plant availability, the company might use metal separators that are located directly between the mixing and dosing unit for the granulate and the material feed of the machine.

Under certain circumstances, the granulate

could contain a small, metallic contaminant that makes its way through the

mixing and dosing unit and into the machine by way of the conveyor pipe. The

metal separator would detect the tiny metal part and expel it safely,

preventing any disruptions to the production process. Because a small amount of

the desired material is also expelled during separation, the volume of granulate

actually reaching the injection moulding machine may fall short of the expected

quantity.

The OPC UA link allows the metal separator to notify the mixing and dosing unit that a certain amount of material has been expelled. At the same time, it provides information as to the volume that needs to be added back into the system to maintain correct calculation. The result is a smooth manufacturing process that produces perfect caps and lids.

Without standardised communication thanks to OPC UA, even the slightest deviations in the quality and flow of granulate could lead to the production of faulty parts, such as weak, under-injected lids. Such defective products often remain unnoticed at first and are later packaged for shipment to the customer without further inspection, virtually ensuring complaints.

Advantages and benefits of OPC UA: optimised plant availability and product quality

By intelligently connecting all of the components involved in production and processing, OPC UA ensures smooth communication in the plastics industry. The exchange of data between metal separators and dosing units, for example, is the key to increasing plant availability and product quality while preventing complaints.

Bartosch Jauernik, an OPC UA expert at Sesotec, says: “We are confronting the challenges of Industry 4.0 head-on and are actively working on the development of OPC UA standards for our devices. Sesotec is one of the first providers of intelligent metal separators for the plastics industry. Our devices can communicate with each other and with other machines, exchange data and optimise themselves.”

Bartosch Jauernik is available to answer questions related to OPC UA and provide practical tips on implementation and processes.