Ready for the next big leap?

Sesotec is taking Food Safety to an entirely new level – with groundbreaking technologies and a brand presence that changes everything.

At IFFA 2025, we are celebrating several world premieres – and you can be there live.

Five world premieres. One mission: Your production will be smarter, safer, and more efficient.

Experience the first generation of X-ray inspection systems that can think.

Artificial intelligence meets high-tech inspection – a duo that not only meets standards but redefines them.

What this means for you:

#NextLevelBranding – Sesotec shows its face. A new one.

We will show you not just what our technology can do – but also who we are.

Bold. Clear. With attitude.

Our new brand appearance makes its debut at IFFA – and you’re invited to experience it first.

What you can expect from us:

Come by as Sesotec turns the page to the next chapter.

#NextLevelSesotec – See it. Feel it. Live it.

World premiere at IFFA 2025

Artificial intelligence is revolutionizing food inspection by increasing accuracy, reducing false rejections, and simplifying compliance. Innovations like the THiNK algorithms and advanced detection systems are driving this transformation, ensuring greater sensitivity and reliability.

It enables the detection of contaminants that are visible to the human eye but differ only slightly in grayscale values from the flawless product – and therefore cannot be detected using conventional methods.

The AI model learns the characteristics of your product by being trained with a large number of flawless examples. If a product deviates from these learned characteristics, it is identified as defective – allowing foreign objects to be precisely located.

Our RAYCON family proudly presents its latest addition: the RAYCON D+ TX, equipped with a cutting-edge TDI detector. But that’s not all – RAYCON now goes hand in hand with our AI-based THiNK Technologies.

Our latest X-ray technology, powered by integrated THiNK AI, can detect contaminants that are visible to the human eye but barely distinguishable from good products in conventional grayscale analysis.

The AI model learns the typical features of a flawless product by analyzing numerous reference samples. If a product deviates from these learned patterns, it is reliably flagged as defective – enabling even the most difficult-to-detect foreign objects to be precisely located.

Your benefit: Maximum detection accuracy – even with the smallest deviations.

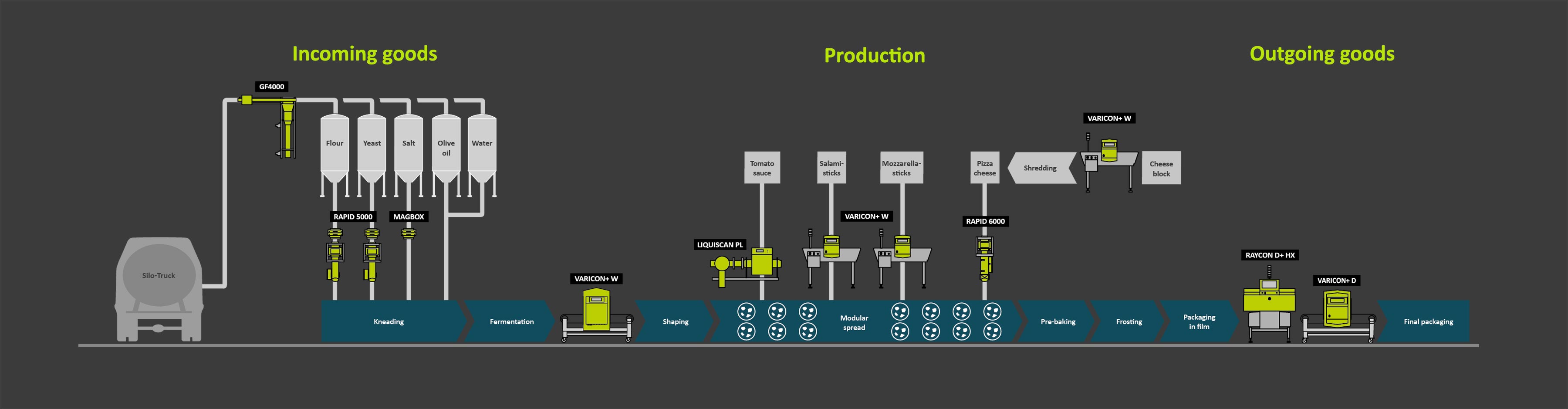

Our metal detectors are specially designed for use in the food industry.

They detect even the smallest metal contaminants in both packaged and unpackaged food products – quickly and reliably, regardless of the product’s size, shape, or position.

They can be used in the middle of the production line to inspect bulk materials or semi-finished products, as well as at the end of the line for final inspection of packaged goods.

Get ready for the world premiere of the NEXT GENERATION!

LIQUISCAN metal separators are specially developed for use in pipeline systems with high hygiene requirements.

They reliably detect and separate both magnetic and non-magnetic metal contaminants from liquid or pasty products – and deliver excellent detection sensitivity, even for products with strong product effects.

Thanks to their short installation length and optional quick-release connectors, these metal separators can be easily integrated into vacuum fillers and pumps. A range of separation units ensures maximum flexibility and seamless integration into complex line controls.

The future of machine control – User-centered software design on a whole new level

Food safety is achieved when many factors work together seamlessly. Insight.HMI, our user-centered operating software, makes every production line more efficient, more effective, and easier to operate – ensuring safety right from the start.

We want to relieve you of this worry and help you ensure the best possible food safety. Our high-end Sesotec devices detect a wide range of foreign bodies in food quickly and reliably. But that's not all: some of our new devices also come with the Compliance Package. The innovative software for and efficient documentation of food production ensures that food is produced in compliance with regulations.

Learn more about the Compliance Package here!

One example is Predictive Maintenance. The maintenance solution analyses real-time data from networked machines and plants and processes the information. Timely intervention before a "standstill" occurs becomes possible. This helps to improve overall plant effectiveness, increase production and reduce costs.

Do you have a specific challenge that needs to be solved or would you like to talk to us in general about food safety?